You’ll achieve better dimensional accuracy by choosing materials with low thermal expansion coefficients like PLA (1.31 × 10⁻⁶ K⁻¹) or ABS (1.25 × 10⁻⁶ K⁻¹) over PETG’s higher 1.73 × 10⁻⁶ K⁻¹. Control your print environment by maintaining 20-25°C ambient temperature and using proper heated bed settings. Account for material expansion in your CAD designs by integrating thermal expansion calculations early in the design process. These fundamentals will reveal advanced techniques for achieving professional-grade dimensional stability.

Choose Low CTE Materials for Dimensional Stability

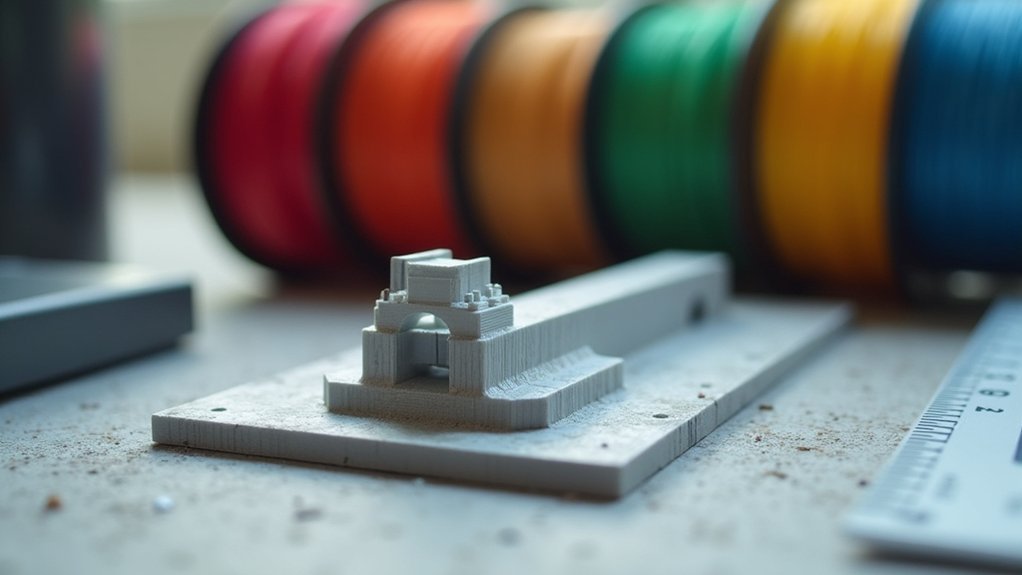

When selecting filaments for precise 3D printing applications, you’ll want to prioritize materials with low coefficients of thermal expansion (CTE) to minimize dimensional changes during printing and cooling cycles.

PLA offers excellent dimensional stability with its low CTE of 1.31 × 10^-6 K^-1, making it ideal for beginners seeking minimal warping.

While ABS has a slightly lower CTE at 1.25 × 10^-6 K^-1, it’s more prone to warping due to higher printing temperatures.

PETG’s higher CTE of 1.73 × 10^-6 K^-1 means greater dimensional changes with temperature variations.

For demanding applications, consider high-performance polymers like PEI (ULTEM 1010), which provides exceptionally low and uniform CTE for superior dimensional stability in critical parts. Many engineers use comparison tools to evaluate thermal expansion properties alongside other material characteristics when making their selection.

Control Print Environment Temperature Consistently

Beyond selecting materials with favorable thermal properties, you must actively manage your printing environment to achieve consistent dimensional accuracy.

Maintain your ambient temperature between 20°C to 25°C throughout the entire print process. Temperature fluctuations cause uneven thermal expansion, leading to warping and dimensional inconsistencies.

Set your heated build plate to material-specific temperatures: 50°C-60°C for PLA, 80°C-110°C for ABS. This prevents warping and guarantees proper layer adhesion. Your nozzle temperature should remain stable within the 200°C-300°C range depending on your filament choice.

Control humidity levels using dehumidifiers, as moisture absorption affects material properties. An enclosed chamber helps regulate ambient temperature and prevents drafts that can compromise print stability.

Install real-time monitoring systems to track temperature variations and make immediate adjustments. Consider using climate control systems or JULABO circulators for precise environmental management in professional applications.

Account for Material Expansion in Part Design

Since thermal expansion coefficients directly impact your part’s final dimensions, you must integrate these material properties into your design calculations from the beginning. You’ll need to compensate for expected dimensional changes by adjusting your CAD models accordingly. Consider geometry optimization to minimize stress concentrations, especially around holes and bridges where thermal expansion can cause cracking.

| Material | Thermal Expansion Coefficient (K⁻¹) |

|---|---|

| PLA | 1.31 × 10⁻⁶ |

| ABS | 1.25 × 10⁻⁶ |

| PETG | 1.73 × 10⁻⁶ |

| Flexifill 98A | 1.12 × 10⁻⁶ |

Select materials with lower thermal expansion coefficients when dimensional stability is critical. Test prototypes under various temperature conditions to validate your design assumptions. Use proper support structures during printing to maintain part shape and minimize thermal stress buildup. Fiber Bragg grating sensors can provide micro-strain accuracy for precise thermal expansion measurement during material characterization.

Frequently Asked Questions

How Do I Measure CTE of Custom or Blended Filaments?

You’ll embed FBG sensors in printed specimens, apply thermal cycles above glass transformation temperatures, measure strain versus temperature data, then calculate CTE from the linear slope while using DSC for crystallinity analysis.

Can Post-Processing Methods Reduce Thermal Expansion Effects in Printed Parts?

You can reduce thermal expansion effects through annealing, which relieves internal stresses and stabilizes material properties. However, material selection with lower thermal expansion coefficients remains more effective than post-processing alone.

Which Filament Has the Lowest CTE for Precision Applications?

You’ll achieve the best dimensional precision with ULTEM 1010, which offers the lowest thermal expansion coefficient among 3D printing filaments. It’s specifically engineered for applications requiring exceptional thermal stability and accuracy.

Do Layer Height and Infill Density Affect Thermal Expansion Behavior?

You’ll find that layer height and infill density don’t greatly affect thermal expansion coefficients. Material choice and print orientation matter much more than these settings for controlling dimensional changes during temperature fluctuations.

How Does CTE Change When Filaments Contain Additives Like Carbon Fiber?

When you add carbon fiber to filaments, you’ll considerably reduce their thermal expansion coefficients. The carbon fibers create a more stable matrix, lowering CTE and improving dimensional stability compared to pure polymers.

In Summary

You’ll achieve better dimensional accuracy by selecting filaments with lower thermal expansion coefficients, maintaining consistent ambient temperatures during printing, and designing parts with material expansion in mind. Don’t overlook how temperature fluctuations affect your prints’ final dimensions. When you’re planning critical tolerances, factor in the CTE values from the start. These three strategies will help you minimize warping and guarantee your printed parts meet specifications consistently every time.

Leave a Reply