You’ll transform your manufacturing operations by integrating 3D printing into production lines, achieving up to 91% cost reductions like Volkswagen Autoeuropa’s €325,000 annual savings. You can accelerate turnaround times from weeks to days while creating custom jigs, fixtures, and machine components on-demand. This technology eliminates costly tooling, reduces inventory waste, and enables profitable short production runs with unprecedented design flexibility. The thorough strategies and real-world applications ahead will guide your successful implementation.

Understanding 3D Printing Technology in Manufacturing Environments

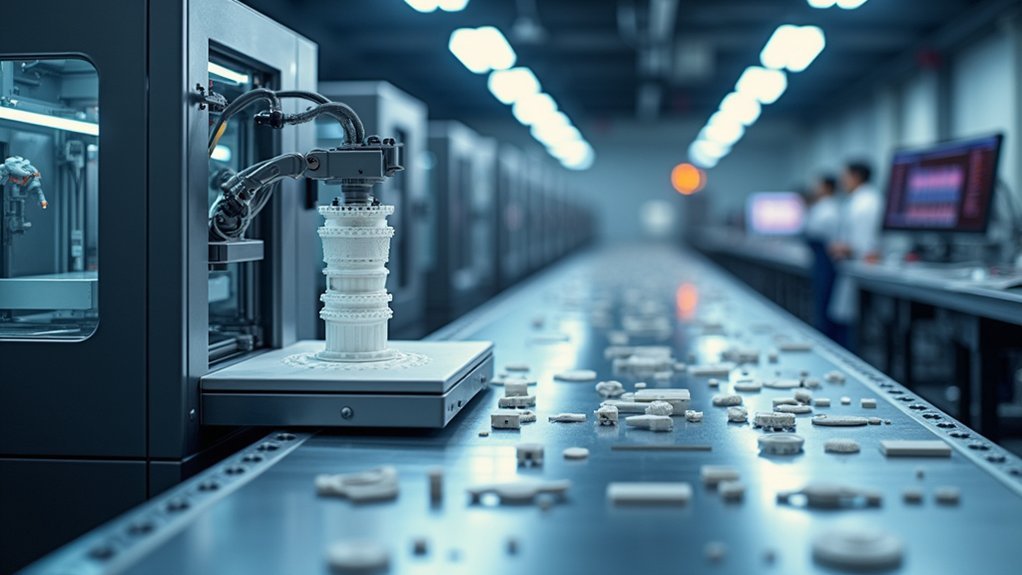

Revolution in manufacturing has arrived through 3D printing technology, fundamentally transforming how you approach production processes. When you integrate this technology into your manufacturing systems, you’re gaining unprecedented capabilities that traditional methods simply can’t match.

You’ll discover that 3D printing enables the creation of complex geometries and intricate designs previously impossible to manufacture, opening doors to enhanced product innovation and customization opportunities.

Your production timelines will dramatically improve since you’ll eliminate the need for costly tooling and molds. Instead of waiting weeks or months, you can complete manufacturing jobs in just days.

This rapid prototyping capability allows you to quickly iterate and test designs, accelerating your time-to-market while maintaining precision and quality standards throughout your production workflow.

Cost Reduction Strategies Through Additive Manufacturing

Beyond the operational advantages of enhanced design capabilities and faster production timelines, 3D printing delivers substantial cost savings that directly impact your bottom line.

Volkswagen Autoeuropa exemplifies this potential, achieving a 91% reduction in custom tool fabrication expenses through additive manufacturing, resulting in €325,000 annual savings.

Volkswagen Autoeuropa cut custom tool costs by 91% with 3D printing, saving €325,000 annually through additive manufacturing.

You’ll experience similar benefits by replacing traditional manufacturing methods—one custom façade company saved $50,000 quarterly using 3D printing.

Your operations become more efficient when you produce jigs and fixtures rapidly, eliminating costly tool reconfiguration.

Creating custom machine components in-house reduces external supplier dependence and overhead costs.

Most importantly, on-demand production minimizes inventory costs and waste, creating an agile manufacturing process that maximizes your cost savings while maintaining production quality.

Accelerating Production Turnaround Times

You’ll find that 3D printing transforms your production timeline by slashing turnaround times from weeks to just days.

Your prototyping cycles accelerate dramatically, letting you iterate designs and test concepts in a fraction of the traditional timeframe.

This speed advantage means you can respond to market demands faster while reducing the bottlenecks that typically slow manufacturing workflows.

Rapid Prototyping Benefits

When manufacturers need custom parts quickly, 3D printing delivers results that traditional methods simply can’t match.

You’ll discover that rapid prototyping transforms your development timeline dramatically. While traditional CNC milling requires weeks or months for setup and execution, 3D printing completes jobs in days.

You can iterate designs rapidly, refining prototypes efficiently without expensive molds or tooling. This streamlined approach cuts costs by over 70% compared to conventional methods, accelerating your path to market readiness.

On-demand production capabilities let you create functional prototypes instantly, providing greater flexibility for testing and development.

Your manufacturing process becomes more agile when you eliminate lengthy setup times. You’re no longer constrained by traditional manufacturing limitations, enabling faster innovation cycles and competitive advantages in today’s fast-paced market.

Lead Time Reduction

Manufacturing efficiency hinges on speed, and 3D printing delivers unprecedented lead time reductions that reshape production schedules entirely. You’ll transform weeks-long processes into day-long operations, dramatically accelerating your turnaround times while positioning yourself ahead of competitors stuck with traditional methods.

| Production Method | Typical Lead Times | 3D Printing Results |

|---|---|---|

| CNC Milling | 3-4 weeks | Under 24 hours |

| Traditional Setup | Days for configuration | Immediate printing |

| Design Iterations | Weeks per cycle | Same-day modifications |

When you eliminate offline setup and tool path configuration, smaller jobs get prioritized instantly. You’ll reduce costs through faster design iterations and rapid prototyping capabilities. Companies integrating 3D printing experience accelerated time-to-market, giving you competitive advantages that traditional manufacturing simply can’t match in today’s fast-paced industrial landscape.

Competitive Advantages of Manufacturing Line Integration

You’ll gain significant competitive advantages when you integrate 3D printing into your manufacturing lines through three key areas.

First, you’ll accelerate your product development cycles with rapid prototyping that lets you test designs in days rather than weeks.

Second, you’ll slash production costs while gaining the flexibility to quickly adapt your manufacturing processes to meet changing market demands.

Rapid Prototyping Benefits

Since traditional prototyping methods can drain budgets and delay product launches, manufacturers who integrate 3D printing into their production lines gain substantial competitive advantages through rapid prototyping capabilities.

You’ll reduce manufacturing costs by over 70% while eliminating expensive molding processes that slow innovation.

Your team can iterate designs in real-time, adapting quickly to market changes that leave competitors scrambling.

Companies like Tucci Hotrods demonstrate this power, slashing turnaround times from weeks to under 24 hours.

You’ll produce complex geometries impossible with traditional methods, revealing innovative product designs that differentiate your offerings.

Cost Reduction Strategies

Money talks in manufacturing, and 3D printing delivers dramatic cost savings that transform your bottom line. When you implement cost reduction strategies through 3D printing, you’ll eliminate expensive tooling investments and slash production expenses.

Your manufacturing line gains these powerful advantages:

- Cut custom tool costs by 91% – Save hundreds of thousands annually like Volkswagen Autoeuropa

- Eliminate costly CNC re-tooling downtime – Keep production flowing without interruption

- Reduce labor costs through ergonomic improvements – Better tools mean more efficient workers

- Slash turnaround times from weeks to hours – Speed kills competition

- Create complex designs without traditional tooling investments – Innovation becomes affordable

You’re not just adopting new technology; you’re restructuring your entire cost structure.

3D printing transforms how you approach manufacturing economics, making customization profitable and rapid iteration standard practice.

Production Flexibility Enhancement

When market demands shift overnight, your 3D printing-integrated production line adapts instantly while competitors scramble with outdated tooling.

Production flexibility enhancement becomes your strategic weapon, enabling rapid pivots in product development without expensive retooling delays. You’ll manufacture customized products without significant cost penalties that traditional methods impose through mold creation and setup changes.

Your design iteration cycle accelerates dramatically, allowing product testing and refinement within days rather than weeks. This agility transforms how you respond to customer specifications and market trends.

Complex geometries that conventional manufacturing can’t achieve become standard offerings, differentiating your products from competitors.

Short production runs become profitable ventures, eliminating minimum order quantities that previously restricted your market responsiveness.

You’ll capture niche opportunities while maintaining cost-effective operations across diverse product lines.

Custom Jigs and Fixtures for Production Efficiency

Precision drives every successful manufacturing operation, and custom jigs and fixtures serve as the backbone of accurate assembly and testing processes.

With 3D printing, you’ll transform how you create these essential tools, dramatically reducing both costs and production time compared to traditional methods.

3D printing revolutionizes jig creation, slashing costs and production time while enabling rapid design iterations for manufacturing excellence.

You can now iterate designs rapidly, making ergonomic improvements and customizations that boost your workflow efficiency. There’s no need for costly re-tooling anymore – you’ll create specific jigs for each production run, optimizing fit and functionality.

- Slash lead times by fabricating alignment jigs in-house

- Boost accuracy with precise logo placement tools

- Eliminate waste through consistent assembly processes

- Enhance quality with perfectly fitted fixtures

- Streamline operations across your entire production line

Machine Components, Covers, and Specialized Holders

You’ll find 3D printing excels at producing machine components that traditional manufacturing can’t easily deliver, from custom-fitted parts to specialized housings tailored to your exact specifications.

Your sensitive equipment needs reliable protection, and 3D-printed covers and guards offer dust shields for optical scanners, laser sensors, and other critical components without complex tooling requirements.

When you’re mounting encoders, control boxes, or other machinery elements, 3D-printed precision mounting solutions streamline integration while reducing both lead times and costs.

Custom Component Creation

As manufacturing demands become increasingly specialized, 3D printing offers an unmatched solution for creating custom machine components that traditional methods can’t efficiently produce.

You’ll discover that integrating 3D printing into your workflow eliminates the frustration of sourcing unavailable parts and waiting for expensive custom manufacturing.

Custom component creation through 3D printing delivers these game-changing advantages:

- Dust covers for optical scanners – Achieve precise fits that protect your sensitive equipment

- Specialized encoder holders and mounts – Source difficult-to-find components instantly

- Large-scale components – Utilize mammoth stereolithography printers for industrial applications

- Rapid prototyping capabilities – Reduce lead times and slash costs considerably

- Custom alignment jigs – Cut assembly time while improving operational efficiency

You’ll transform your production line with unprecedented flexibility and speed.

Protective Covers and Guards

Beyond creating one-off components, 3D printing excels at manufacturing protective covers and guards that shield your valuable machinery from damage and contamination.

You can produce custom dust covers that protect sensitive optical scanners and laser sensors, ensuring they maintain operational reliability throughout their lifespan. When you need specialized holders for encoders or other critical components, 3D printing reduces both lead times and sourcing costs compared to traditional manufacturing methods.

Large-scale printers like Mammoth stereolithography systems enable you to create bigger protective components that conventional methods can’t easily produce.

These custom guards enhance safety and efficiency in your manufacturing environment by providing precise fits and integrated functionalities, ultimately improving your operational workflows while protecting expensive equipment investments.

Precision Mounting Solutions

Precision becomes paramount when designing mounting solutions that integrate seamlessly with existing manufacturing equipment.

You’ll find that 3D printing enables customized precision mounting solutions that traditional manufacturing simply can’t match. These tailored components guarantee peak functionality while reducing costly downtime and compatibility issues.

Consider how precision mounting solutions revolutionize your production environment:

- Enhanced stability – Custom-fitted mounts eliminate vibration and misalignment issues

- Perfect compatibility – Components designed specifically for your unique equipment specifications

- Rapid deployment – Prototype, test, and implement solutions in days rather than weeks

- Cost efficiency – Eliminate expensive tooling and minimum order requirements

- Adaptive design – Modify mounting solutions instantly as production needs evolve

Through 3D printing, you’re not limited by standard mounting hardware constraints, enabling truly enhanced integration.

Connecting Pieces for Streamlined Material Handling

When you’re managing laser sintering operations, maintaining clean and efficient material flow becomes critical to your production success.

Custom connecting pieces designed through 3D printing solve the persistent challenge of transferring fine nylon powder between silos and machines without creating mess or handling complications.

These tailored components guarantee seamless material transfer, directly enhancing your manufacturing operational efficiency.

You’ll eliminate downtime previously spent sourcing or modifying existing parts, as you can quickly produce exactly what your production line requires.

When setup adjustments become necessary, you’ll adapt rapidly to varying production needs without extensive delays.

This approach cuts costs while minimizing material waste, since you’re only producing components your specific requirements demand.

The result transforms your entire production workflow into a more streamlined, responsive operation.

Quality Control Systems and Testing Applications

As quality demands intensify across manufacturing sectors, 3D printing transforms how you approach testing and inspection processes.

You’ll discover that custom fixtures and jigs eliminate traditional tooling constraints while accelerating your quality control workflows.

RapidFit exemplifies this revolution by integrating snap-fits and clips directly into testing components, delivering unprecedented accuracy for automotive applications.

You can now customize fixtures for specific car models, ensuring repeatability while reducing time to market.

Consider these transformative benefits:

- Slash prototyping costs through rapid iteration and testing cycles

- Eliminate lengthy lead times that traditionally plague quality assurance

- Achieve pinpoint accuracy with model-specific fixture customization

- Streamline production lines by reducing traditional tooling dependencies

- Accelerate time to market through enhanced testing processes

Companies like Philips prove that integrating 3D-printed quality control components delivers measurable efficiency gains across manufacturing operations.

Prototyping Within Production Workflows

Beyond perfecting your quality control processes, 3D printing revolutionizes how you handle prototyping throughout your entire production workflow.

You’ll reduce prototyping costs by over 70% while bringing products to market faster through rapid design iteration. By integrating 3D-printed prototypes directly into your production line, you eliminate expensive molds and make quick adjustments based on testing feedback.

You can create functional prototypes in-house within days instead of weeks, dramatically enhancing your development efficiency.

Advanced 3D printing technologies let you produce intricate designs impossible with traditional methods, expanding innovation possibilities.

This integration helps you manage inventory levels effectively, reducing overproduction costs and excess stock while maintaining ideal workflow efficiency throughout your manufacturing process.

Bridge Manufacturing for Medium-Volume Runs

While prototyping establishes your design foundation, bridge manufacturing with 3D printing transforms how you handle medium-volume production runs between initial development and full-scale manufacturing.

You’ll eliminate extensive tooling requirements while dramatically reducing lead times from weeks to days. This approach accelerates your time-to-market and positions you ahead of competitors who’re stuck in traditional manufacturing cycles.

Bridge manufacturing with 3D printing delivers game-changing advantages:

- Slash financial risk by testing market demand with limited quantities before committing to large-scale production

- Adapt instantly to customer feedback without expensive re-tooling costs

- Eliminate material waste through precise on-demand production

- Reduce excess inventory by aligning production with actual market needs

- Customize rapidly as market trends shift

You’re no longer constrained by traditional manufacturing limitations when bridging the gap between prototype and production.

Supply Chain Transformation and Localized Production

You’ll transform your supply chain considerably by implementing 3D printing for localized production, enabling on-demand manufacturing that eliminates traditional inventory bottlenecks.

Your production costs drop considerably when you can manufacture parts directly within your facilities, reducing dependency on external suppliers and lengthy transportation networks.

You’ll gain unprecedented flexibility to respond quickly to customer demands while cutting logistics expenses through location-independent manufacturing capabilities.

On-Demand Production Benefits

As modern manufacturing shifts toward customer-centric models, 3D printing’s on-demand production capabilities are revolutionizing traditional supply chains by eliminating the need for large inventory stockpiles.

You’ll discover that adoption of 3D printing transforms how you approach manufacturing efficiency and cost management.

Transform Your Manufacturing Operations:

- Slash inventory costs – You’ll eliminate expensive warehousing and reduce capital tied up in excess stock.

- Accelerate delivery times – Your customers receive products faster with minimal lead times and no tooling delays.

- Respond instantly – You can pivot production based on real-time demand without financial penalties.

- Manufacture locally – You’ll cut transportation costs while serving customers closer to their locations.

- Customize affordably – You can offer personalized products without traditional mass-production constraints.

Reducing Inventory Costs

Since traditional manufacturing requires substantial upfront investment in inventory that may never sell, 3D printing fundamentally reshapes your cost structure by producing items only when orders arrive.

You’ll eliminate warehousing expenses, reduce insurance costs for stored goods, and free up working capital previously tied to excess stock. This on-demand approach means you won’t face obsolete inventory write-offs or markdowns on unsold products.

Your inventory costs drop dramatically as 3D printing enables just-in-time production cycles. You can manufacture closer to customers, cutting transportation and storage requirements while maintaining rapid response times.

This streamlined approach reduces overhead associated with inventory management systems, personnel, and facilities. By minimizing stock levels, you’ll achieve better cash flow and operational efficiency throughout your supply chain.

Local Manufacturing Advantages

When you establish manufacturing facilities closer to your customer base, 3D printing transforms your entire supply chain by eliminating the need for complex global distribution networks.

You’ll dramatically reduce transportation costs while cutting your carbon footprint through localized production.

Local manufacturing with 3D printing delivers powerful advantages that revolutionize how you operate:

- Slash logistics expenses by producing items where they’re needed most

- Respond instantly to market changes without maintaining massive inventories

- Customize products at scale for specific regional preferences and demands

- Accelerate time-to-market by eliminating lengthy tooling and setup processes

- Enhance supply chain flexibility through rapid design adjustments based on real-time feedback

You’ll gain competitive advantages while building resilient operations that adapt quickly to customer needs and market fluctuations.

Overcoming Integration Challenges and Regulatory Compliance

Though 3D printing offers transformative potential for modern manufacturing, you’ll face substantial hurdles when integrating this technology into established production environments.

Regulatory compliance becomes paramount, especially in aerospace and healthcare sectors where strict safety standards govern operations. Manufacturers must navigate complex certification processes that vary by industry and region, potentially delaying technology adoption.

Complex certification requirements across varying industry standards can significantly slow 3D printing adoption in highly regulated manufacturing sectors.

You’ll need robust cybersecurity measures to protect intellectual property and sensitive design files from cyber threats inherent in digital manufacturing.

Staff retraining presents another significant challenge as your workforce adapts to new technologies and processes beyond traditional methods.

Additionally, you must address supply chain visibility issues since localized, on-demand production disrupts established logistics and inventory management practices, requiring thorough workflow restructuring.

Industry-Specific Applications and Case Studies

Across multiple industries, 3D printing has moved beyond prototyping to revolutionize production workflows and deliver measurable business results.

You’ll find compelling evidence of transformation when examining how companies have replaced traditional manufacturing methods with additive solutions.

Consider these remarkable achievements:

- Volkswagen Autoeuropa slashed custom tool costs by 91% – from €325,000 annually to just €10 per tool

- General Electric’s fuel nozzles became 25% lighter, dramatically improving aircraft fuel efficiency

- Siemens enhanced gas turbine efficiency while cutting lead times considerably

- Adidas delivers personalized midsoles through on-demand production, eliminating inventory waste

- Automotive manufacturers reduce prototyping costs by over 70% while enabling complete customization

You’re witnessing 3D printing’s evolution from experimental technology to production-ready solution that delivers quantifiable ROI across sectors.

Future-Proofing Manufacturing With Smart Production Systems

As manufacturing enters its next evolutionary phase, you’re positioned to leverage smart production systems that transform 3D printing from isolated operations into interconnected, intelligent networks. These systems integrate real-time data analytics to optimize your printing processes while enabling predictive maintenance that identifies part needs before failures occur.

| Capability | Traditional Manufacturing | Smart Production Systems |

|---|---|---|

| Lead Times | Weeks to months | Hours to days |

| Customization | Limited, costly | Scalable personalization |

| Maintenance | Reactive repairs | Predictive prevention |

| Decision Making | Manual analysis | AI-driven insights |

| Production Flexibility | Fixed schedules | On-demand generation |

You’ll achieve unprecedented operational efficiency through automation and Industry 4.0 technologies. By integrating advanced materials and AI into your 3D printing workflows, you’re positioning your business to deliver personalized products at scale without cost increases, ensuring competitiveness in today’s agile manufacturing landscape.

Frequently Asked Questions

How Is 3D Printing Used in the Manufacturing Industry?

You’ll use 3D printing for rapid prototyping, on-demand custom parts production, and creating intricate designs that traditional methods can’t achieve. It’ll reduce your costs, speed up iterations, and improve supply chain flexibility considerably.

What Is the Scope of 3D Printing in the Manufacturing Industry?

You’ll find 3D printing’s scope spans prototyping, low-volume production, custom parts, tooling, and end-use components across aerospace, automotive, healthcare, and consumer goods industries, revolutionizing traditional manufacturing approaches.

What Are the Applications of 3D Printing in Manufacturing Industry?

You’ll find 3D printing creates rapid prototypes, custom jigs, fixtures, and complex components. It enables on-demand part production, reduces tooling costs, shortens lead times, and allows quick responses to market demands.

In What Ways Is 3D Printing Helping the Product Development Process in Manufacturing?

You’ll accelerate your product development through rapid prototyping that cuts timeline from months to days. You’re also reducing costs by 70% while enabling quick design iterations and creating complex geometries impossible with traditional manufacturing methods.

Leave a Reply