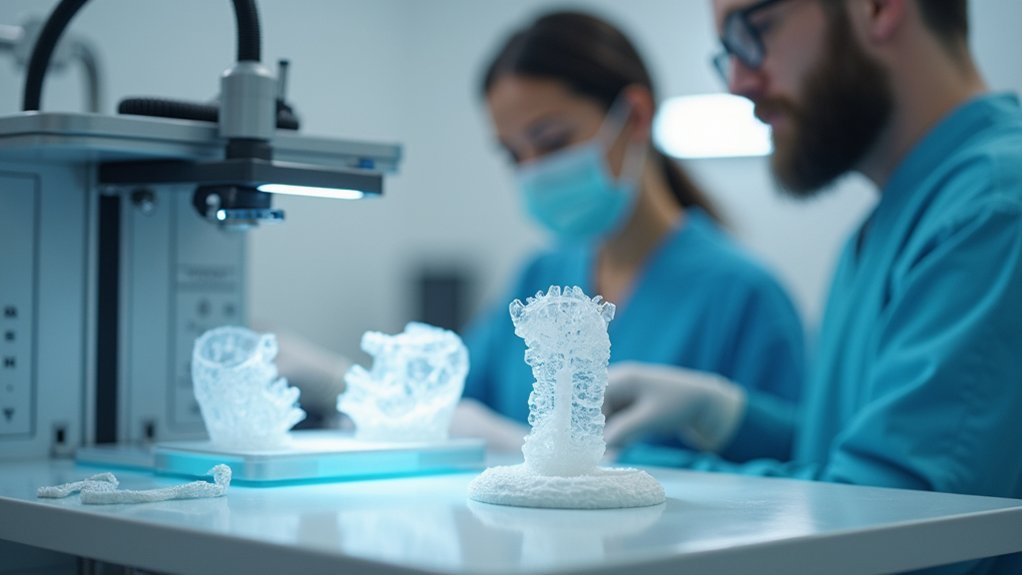

3D printing revolutionizes patient-specific implants in three transformative ways. First, you’ll experience enhanced surgical precision as custom implants match your unique anatomy perfectly, reducing procedure time by an average of 62 minutes compared to traditional one-size-fits-all approaches. Second, advanced biocompatible materials like poly (L-lactide-co-D, L-lactide) combined with β-tricalcium phosphate accelerate your recovery while preventing complications. Third, point-of-care manufacturing eliminates lengthy wait times by producing your tailored implants on-site, and these innovations reveal even deeper benefits.

Enhanced Surgical Precision Through Patient-Specific Design

While traditional off-the-shelf implants follow a one-size-fits-all approach, 3D printing revolutionizes surgical precision by creating patient-specific implants that match your unique anatomy.

These customized designs greatly improve fit and function, delivering enhanced surgical outcomes compared to conventional options.

Patient-specific 3D-printed implants deliver superior fit and function, resulting in dramatically improved surgical outcomes over standard implant solutions.

When surgeons use 3D-printed anatomical models as surgical guides, they reduce procedure time by an average of 62 minutes while increasing overall efficiency.

Your patient-specific implants facilitate better alignment and promote osseointegration, enhancing longevity and effectiveness.

The technology enables rapid design modifications based on real-time surgeon feedback, improving adaptability during procedures.

Accelerated Recovery With Biocompatible Materials

Beyond surgical precision, your recovery timeline greatly improves when surgeons use advanced biocompatible materials in 3D-printed implants.

These patient-specific implants utilize poly (L-lactide-co-D, L-lactide) combined with β-tricalcium phosphate, promoting superior integration with the body and enhancing healing processes.

You’ll experience markedly reduced recovery times because customized designs perfectly match your anatomical structures, ensuring ideal fit and alignment.

The enhanced mechanical properties of these implants, including Young’s modulus matching your bone characteristics, prevent stress shielding complications that could slow healing.

3D printing enables seamless integration into surgical workflows, minimizing operating time and accelerating your post-surgery recovery.

Studies consistently show these personalized solutions deliver improved therapeutic outcomes while reducing postoperative discomfort, ultimately providing you with accelerated healing and faster return to normal activities.

Point-of-Care Manufacturing Transforms Treatment Delivery

Point-of-care (POC) 3D printing revolutionizes your treatment experience by enabling healthcare facilities to manufacture patient-specific implants directly on-site, eliminating lengthy wait times that traditionally delay surgical interventions.

This seamless integration into surgical planning workflows enhances precision through customized solutions tailored to your unique anatomy.

You’ll benefit from improved therapeutic outcomes as healthcare teams create personalized medical devices specifically designed for your body.

Research demonstrates that 3D printing reduces surgical time by an average of 62 minutes, streamlining your operation and improving overall efficiency.

Point-of-care manufacturing transforms treatment delivery by providing immediate access to biodegradable implants that perfectly match your anatomical requirements.

However, regulatory compliance remains essential for ensuring the safety and efficacy of these innovative solutions.

Frequently Asked Questions

How Can 3D Printing Be Used to Create Custom Medical Devices for Patients?

You can create custom medical devices by using your CT scan or MRI data to generate precise digital models, then 3D print patient-specific implants, prosthetics, and surgical guides that perfectly match your unique anatomy.

What Are the Advantages of 3D Printing in Dental Implants?

You’ll get perfectly fitted dental implants that integrate better with your bone structure. 3D printing reduces your surgery time, speeds recovery, and lets surgeons customize designs specifically for your mouth’s unique anatomy.

How Can 3D Printing Revolutionize Healthcare, Particularly in the Creation of Customized Prosthetics and Medical Implants?

You’ll experience perfectly fitted implants tailored to your unique anatomy, reducing surgery time by over an hour while cutting costs substantially. You’ll benefit from lightweight designs and faster recovery times with improved stability.

How Has 3D Printing Changed Healthcare?

You’ve witnessed 3D printing transform healthcare by enabling personalized prosthetics, reducing surgery times, cutting costs considerably, and improving patient outcomes. It’s revolutionized treatment approaches, enhanced surgical precision, and made complex medical geometries possible.

Leave a Reply