You can revolutionize construction with five game-changing 3D printed components: precast concrete wall panels that deliver precision and minimize waste, custom architectural features enabling intricate decorative facades, load-bearing columns and support beams manufactured with advanced materials for superior structural integrity, modular housing units completing projects in days rather than weeks, and complex geometric joints eliminating traditional fasteners. These components reduce production time by 90% while enhancing design flexibility and sustainability. Continue exploring to discover how these innovations transform modern building practices.

Precast Concrete Wall Panels and Structural Elements

Revolution is transforming the construction industry as 3D printing technology reshapes how you can produce precast concrete wall panels and structural elements.

You’ll find this innovation dramatically reduces production time and labor compared to traditional construction methods while maintaining high quality standards.

With customizable design capabilities, you can create unique architectural features and complex shapes that weren’t feasible before.

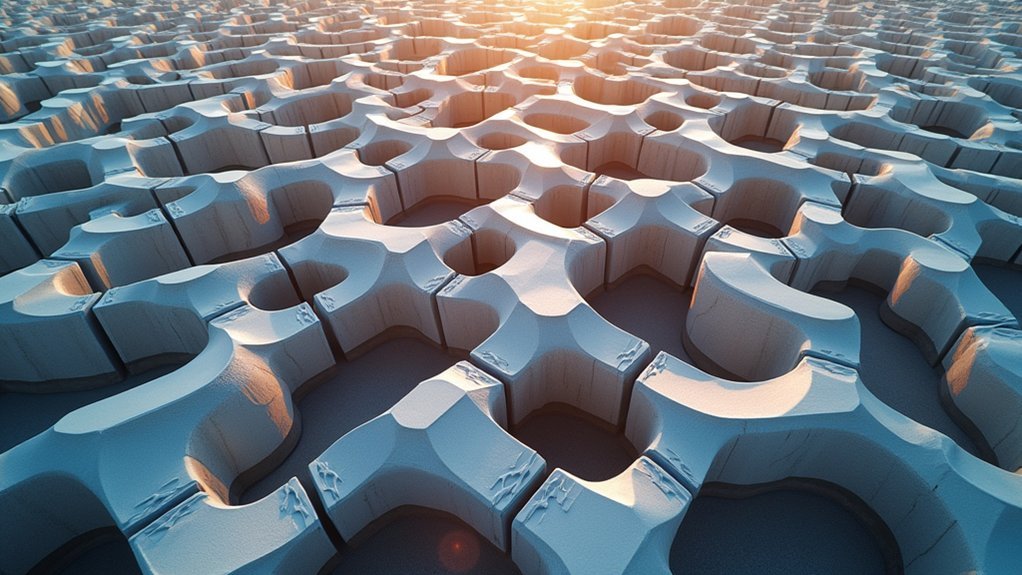

3D printing unlocks unprecedented architectural freedom, enabling complex geometries and custom designs impossible with traditional concrete construction methods.

The precision of 3D printing technology guarantees accurate dimensions while minimizing material usage and waste.

You’ll appreciate the rapid deployment potential, as building components can be ready within days of design completion.

The enhanced structural integrity comes from utilizing high-strength materials specifically tailored for load-bearing requirements, making these precast concrete elements both efficient and reliable for modern construction projects.

Custom Architectural Features and Decorative Facades

While traditional construction methods often limit architectural creativity to basic geometric forms, 3D printing technology empowers you to bring even the most intricate decorative facades and custom architectural features to life.

You’ll discover that large-scale printing enables quick, cost-effective production of unique building materials while minimizing waste through precise manufacturing techniques.

Your designs can accommodate diverse architectural styles and local environmental conditions with unprecedented flexibility.

Through CAD software integration, you can seamlessly incorporate complex architectural elements that enhance both functionality and visual appeal.

These 3D printed decorative facades aren’t just visually striking—they can incorporate sustainable materials that boost energy efficiency and reduce environmental impact, revolutionizing how you approach construction projects with innovative design possibilities.

Load-Bearing Columns and Support Beams

Beyond creating stunning visual elements, 3D printing technology transforms the very foundation of structural engineering by enabling you to manufacture load-bearing columns and support beams with unprecedented precision and efficiency.

Construction professionals can now utilize concrete 3D printing to produce large scale structural components through advanced CAD models, ensuring accurate dimensions and ideal structural integrity.

Advanced CAD models enable construction professionals to 3D print large-scale structural components with precise dimensions and optimal integrity.

The MaxiPrinter’s 12.5-meter printing capacity allows you to create entire columns and support beams in single continuous pours, greatly reducing material waste and construction time.

You’ll achieve superior strength using specialized materials and pumpable concrete formulations specifically designed for structural applications.

This technology’s adaptability lets you integrate complex geometric shapes that enhance both aesthetic appeal and structural performance in modern construction projects.

Modular Housing Units and Prefabricated Sections

As construction demands shift toward faster project completion and enhanced customization, 3D printing technology revolutionizes modular housing production by enabling you to manufacture entire prefabricated sections with remarkable speed and precision.

You can complete projects in days rather than weeks using advanced concrete printer systems like the MaxiPrinter, which handles components up to 12.5 meters long across 150 m² print areas.

Off-site production lets you maintain superior quality control while avoiding weather-related delays that plague traditional construction sites.

You’ll minimize material waste through precise concrete application, supporting sustainable building practices.

The technology enables complex architectural features that conventional methods can’t achieve, giving you unprecedented design flexibility for modular housing units.

Complex Geometric Joints and Connection Systems

When you design complex geometric joints for large-scale 3D printed components, you’re revealing architectural possibilities that traditional construction simply can’t match.

These connection systems enable unique structural configurations while maintaining exceptional structural integrity throughout your building.

You’ll create customized joints that accommodate specific load-bearing requirements without additional fasteners. Using computer-aided design software, you can develop intricate joint designs that translate directly into printed components, ensuring perfect fit and alignment during assembly.

The ability to print complex geometries in single pieces eliminates material waste and reduces labor costs compared to traditional multi-component fabrication.

Advanced materials like specially formulated concrete provide enhanced durability and environmental resistance, extending your structure’s lifespan while delivering unprecedented design freedom.

Frequently Asked Questions

What Large-Scale Things Can You Print With 3D Printing?

You can 3D print aerospace components, automotive parts, medical implants, furniture, sculptures, and consumer products. However, for building components specifically, you’ll create walls, structural poles, urban furniture, and entire homes efficiently.

How Much Is a 1000 Sq Ft 3D Printed House?

You’ll pay between $100,000 to $200,000 for a 1000 sq ft 3D printed house. You’re saving up to 50% compared to traditional construction while getting your home built in just 24-48 hours.

What Materials Are Used in 3D Printed Buildings?

You’ll find concrete and special mortar are most common in 3D printed buildings. You can also use plastics, metals, and locally sourced materials like rice waste for sustainable construction.

What Is the Largest Size You Can 3D Print?

You can 3D print objects up to 12.5 meters in length with advanced concrete printers like the MaxiPrinter, which covers 150 m² and reaches 7 meters range for large-scale construction projects.

Leave a Reply