You can leverage PEEK filament’s exceptional 400°C temperature resistance for critical aerospace engine components, biocompatible medical implants, automotive heat shields, oil and gas pipeline valves, and high-temperature electrical connectors. Its superior chemical resistance makes it perfect for downhole extraction tools, custom orthopedic devices, and electronic housings in extreme environments. PEEK’s flame-resistant properties and structural integrity under thermal stress enable applications that conventional plastics can’t handle, and there’s much more to discover about optimizing these specialized manufacturing opportunities.

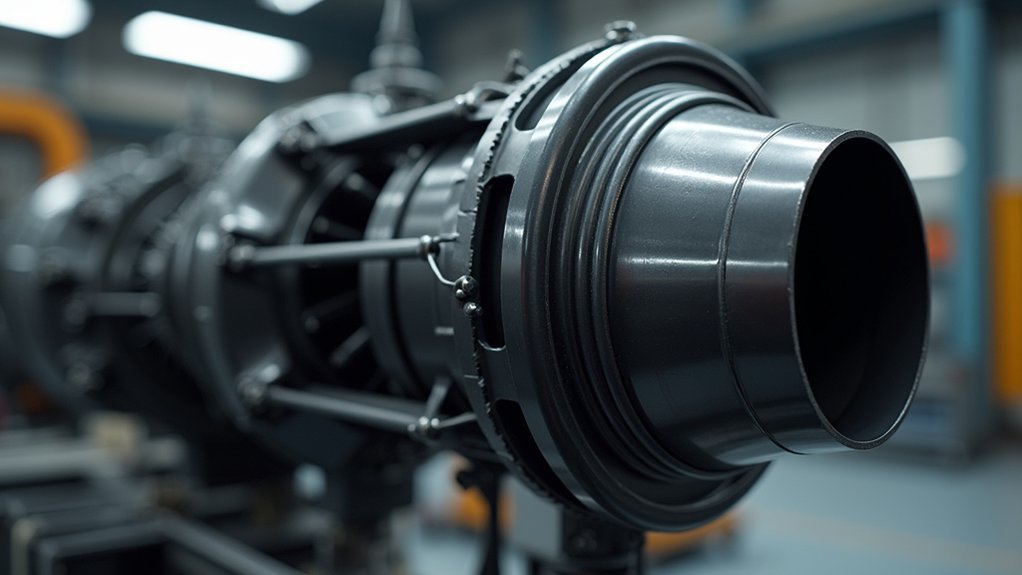

Aircraft Engine Components and Structural Parts

PEEK filament’s exceptional temperature resistance and chemical durability make it an ideal choice for manufacturing aircraft engine components through FDM printing.

PEEK’s superior thermal properties and chemical resistance position it as the premier material for critical aerospace engine applications via additive manufacturing.

You’ll find that PEEK’s ability to withstand temperatures between 360°C and 400°C during printing translates to components that perform reliably in demanding engine environments. The material’s resistance to hydrocarbons and acids protects against fuel and lubricant exposure, while its low outgassing properties guarantee safety in confined aircraft spaces.

You can produce complex brackets, housings, and fasteners that weren’t feasible with traditional manufacturing methods. The flame resistant properties of PEEK make these printed components particularly valuable for aerospace applications where strict fire and smoke regulations must be met.

These PEEK components contribute considerably to weight reduction, enhancing fuel efficiency without compromising structural integrity. The material’s high crystallinity and optimized printing parameters deliver tensile strengths comparable to injection-molded parts, making it essential for critical support structures and thermal management systems.

Biocompatible Medical Implants and Surgical Instruments

When you’re developing medical implants and surgical instruments, FDM printing with specialized PEEK filaments opens unprecedented possibilities for biocompatible applications.

Invibio’s PEEK-OPTIMA™ AM filament and Evonik’s carbon-fiber reinforced variants enable you to create personalized implants that match patient anatomy precisely. You’ll benefit from PEEK’s inherent biocompatibility, which reduces immune rejection and inflammation risks while meeting medical-grade standards for safe tissue contact.

Carbon-fiber reinforcement lets you adjust elastic modulus and tensile strength to approximate natural bone properties, improving load-bearing performance. You can incorporate additives like hydroxyapatite to promote bone cell attachment and mineralization.

Over 100 personalized PEEK implants have proven successful in thoracic surgeries, demonstrating clinical feasibility. The technology enables complex scaffold architectures for tissue engineering while providing sterilizable, durable instruments for surgical applications.

This manufacturing approach offers near-zero wastage during fabrication while enabling the integration of multiple components into a single part for enhanced functionality.

Automotive Engine Bay Components and Heat Shields

As temperatures soar beyond 300°C in automotive engine bays, you’ll find PEEK filament delivers the exceptional thermal resistance needed for critical components and heat shields.

You’ll benefit from PEEK’s superior chemical resistance against automotive fluids while maintaining structural integrity under extreme mechanical stress. Its low moisture absorption guarantees your components won’t degrade over time, making it ideal for long-term automotive applications.

When you’re designing heat shields, PEEK’s lightweight properties reduce overall vehicle weight without compromising protection. PEEK components require proper ventilation and fume extraction systems during printing to ensure safe manufacturing conditions.

FDM technology lets you create complex geometries that optimize heat dissipation and component placement.

- Temperature champions: PEEK withstands up to 300°C while maintaining mechanical properties

- Chemical fortress: Resists automotive fluids, oils, and harsh engine bay chemicals

- Weight advantage: Lighter than metal alternatives without sacrificing durability

- Design freedom: Complex geometries possible through FDM manufacturing

Oil and Gas Pipeline Valves and Seals

You’ll find PEEK filament excels in oil and gas pipeline applications where valves and seals must withstand aggressive chemicals, including hydrocarbons and acids that would degrade conventional materials.

Your 3D-printed components can handle extreme pressures without deformation while maintaining structural integrity from -50°C to 250°C.

These temperature stability benefits make PEEK ideal for critical sealing applications where consistent performance prevents costly leaks and system failures. PEEK-based sealing solutions can deliver 2x longer service life compared to alternative materials in demanding oil and gas environments.

Chemical Resistance Properties

PEEK filament’s exceptional chemical resistance makes it an ideal choice for oil and gas pipeline valves and seals, where components must withstand aggressive environments containing acids, solvents, and hydrocarbon-based substances.

You’ll find PEEK maintains stability against most chemicals encountered in these operations, including gasoline, methane, and hydrogen sulfide. While it resists nearly all substances, you should note exceptions like concentrated sulfuric and hydrofluoric acids. However, certain solvents such as methylene chloride, DMSO, and THF may cause swelling in PEEK.

For your oil and gas applications, PEEK’s chemical resistance provides:

- Broad spectrum protection against acids, organic solvents, and inorganic substances

- Fuel compatibility with gasoline and petroleum-based products commonly found in pipelines

- Steam resistance for high-pressure downhole applications up to 260°C

- Alkali stability ensuring longevity in harsh chemical environments

High Pressure Performance

Performance under extreme pressure conditions separates PEEK filament from conventional materials in critical oil and gas infrastructure. You’ll find PEEK’s semicrystalline structure maintains dimensional stability while enduring cyclic pressure loads that destroy weaker polymers. The material’s exceptional wear resistance prevents degradation in valve seats and seals, where continuous friction under pressure typically causes rapid failure.

| Pressure Challenge | PEEK Solution |

|---|---|

| Cyclic loading fatigue | Superior fatigue resistance maintains seal integrity |

| Valve seat wear | Exceptional abrasion resistance extends service life |

| Chemical degradation | Strong hydrocarbon resistance prevents material breakdown |

| Thermal expansion | Dimensional stability up to 250°C prevents leakage |

| Dynamic sealing stress | Carbon-fiber reinforcement increases stiffness and durability |

Carbon-fiber-reinforced PEEK variants deliver enhanced stiffness, making them ideal for demanding pipeline applications where failure isn’t an option. This high-performance thermoplastic demonstrates excellent mechanical and chemical resistance properties specifically engineered for the harsh operating conditions found in aerospace, automotive, and medical industries.

Temperature Stability Benefits

While conventional polymers buckle under extreme heat, PEEK filament maintains its structural integrity at continuous service temperatures up to 260°C (500°F), making it indispensable for oil and gas pipeline components.

You’ll find that PEEK’s thermal stability guarantees your printed valve seats and seals retain dimensional accuracy during prolonged exposure to elevated temperatures. This reliability translates to extended maintenance intervals and reduced operational downtime in critical pipeline systems.

The material’s exceptional chemical resistance ensures compatibility with harsh hydrocarbons and corrosive substances commonly encountered in oil and gas operations.

- Glass-filled PEEK grades offer enhanced stiffness and lower thermal expansion for superior structural stability

- Carbon fiber fillers improve heat dissipation, preventing localized overheating in dynamic seal components

- 5000-hour testing demonstrates almost unchanged strength under harsh 260°C conditions

- Thermal cycling resistance maintains tight tolerances essential for leak-proof sealing applications

High-Temperature Electrical Connectors and Insulators

You’ll find PEEK filament excels in creating electrical connectors that maintain performance at temperatures up to 250°C where standard plastics fail.

Your printed components won’t degrade when exposed to oils, acids, or aggressive chemicals that typically destroy conventional connector materials.

You can enhance structural strength by incorporating carbon fiber reinforcement, enabling thinner walls while preserving the exceptional insulating properties needed for high-voltage applications. These properties make PEEK ideal for manufacturing D-Connector types used in ultra-high vacuum environments where both chemical resistance and dimensional stability are critical.

Thermal Resistance Benefits

When designing electrical components for extreme environments, PEEK filament’s exceptional thermal resistance becomes your most valuable asset.

You’ll find that PEEK maintains its electrical insulation properties even at temperatures reaching 250°C continuously, ensuring your connectors won’t fail when heat escalates. Unlike conventional materials that degrade under thermal stress, PEEK’s stability under mechanical load guarantees reliable performance throughout your component’s lifespan.

The material’s inherently flame resistant nature provides an additional safety margin when electrical faults occur, automatically self-extinguishing to prevent fire propagation in your systems.

Key thermal resistance benefits for your electrical applications:

- Dimensional stability – Your components won’t warp or change size with temperature fluctuations

- Long-term reliability – Maintains mechanical properties during extended high-temperature operation

- Superior insulation – Electrical properties remain consistent across extreme temperature ranges

- Thermal management – Helps distribute heat effectively, reducing thermal stress on connections

Chemical Inertness Properties

Beyond thermal stability, PEEK filament’s remarkable chemical inertness makes it indispensable for electrical connectors and insulators operating in corrosive environments. You’ll find PEEK maintains integrity against diluted acids up to 37% concentration and resists most bases, outperforming standard plastics like PVC. This chemical stability preserves your connector’s dielectric properties even when exposed to steam, seawater, or industrial chemicals.

| Chemical Type | PEEK Resistance | Performance Notes |

|---|---|---|

| Diluted Acids | High | Up to 37% HCl, acetic acid |

| Concentrated Bases | Limited | Requires evaluation |

| Common Solvents | Variable | Avoid methylene chloride, DMSO |

When you’re 3D printing complex insulating geometries, PEEK’s chemical durability guarantees long-term reliability in aerospace, automotive, and industrial applications where chemical attack could compromise electrical performance. The material demonstrates excellent resistance to organic and inorganic compounds including methanol and various acids over extended exposure periods.

Carbon Fiber Enhancement

Carbon fiber reinforcement transforms PEEK filament into an even more formidable material for high-temperature electrical connectors and insulators.

You’ll find that adding carbon fibers boosts tensile and flexural strength by up to 20%, while considerably increasing stiffness for demanding applications. The enhanced thermal stability guarantees your components won’t deform under extreme heat, maintaining dimensional stability throughout thermal stress cycles.

When you’re printing electrical connectors, you’ll benefit from these key enhancements:

- Superior mechanical strength – Carbon fibers dramatically increase tensile and flexural properties

- Enhanced thermal resistance – Maintains performance in high-temperature environments without degradation

- Improved dimensional stability – Resists warping and deformation under thermal cycling

- Flame-retardant ratings – Often achieves V0 classification for enhanced safety compliance

The material provides electronic conductors functionality while maintaining excellent insulation properties where needed. These improvements make carbon fiber-reinforced PEEK ideal for aerospace, automotive, and industrial electrical applications.

Industrial Jigs and Manufacturing Fixtures

Since traditional metal jigs and fixtures often create bottlenecks in manufacturing due to long lead times and high costs, PEEK filament offers manufacturers a compelling alternative for producing industrial tooling through FDM 3D printing.

You’ll benefit from PEEK’s exceptional chemical resistance and high-temperature properties, making it ideal for demanding manufacturing environments. The lightweight design reduces worker fatigue while maintaining precision up to thousandths of an inch for quality control applications.

You can rapidly customize fixtures for assembly lines without expensive tooling investments. PEEK’s durability protects sensitive product surfaces during handling, while its thermal stability guarantees consistent performance in high-temperature processes. The strength-to-weight ratio can be equal or superior to traditional machined metal parts.

This additive manufacturing approach cuts production costs, shortens lead times, and enables on-demand production for low-volume manufacturing aids.

Aerospace Fuel System Components

When aerospace engineers face the critical challenge of designing fuel system components that must withstand extreme temperatures, corrosive chemicals, and demanding operational conditions, PEEK filament emerges as a game-changing material for FDM manufacturing.

You’ll find PEEK’s chemical resistance guarantees your bearings and seals maintain stable operation throughout their service life. The material’s ability to withstand extreme fuel system temperatures makes it ideal for both commercial and military aircraft applications. PEEK’s low outgassing properties ensure minimal contamination in sensitive fuel system environments.

With FDM manufacturing, you can create complex geometries that traditional methods can’t achieve, enabling innovative component designs.

FDM manufacturing unlocks complex geometries impossible with conventional production methods, revolutionizing aerospace component design possibilities.

Key advantages of PEEK filament for aerospace fuel systems:

- Weight reduction up to 60% compared to metallic components

- Chemical stability against aviation fuels and hydraulic fluids

- Rapid prototyping capabilities for testing custom components

- Enhanced reliability reducing maintenance costs and downtime

Custom Patient-Specific Orthopedic Devices

You can create orthopedic implants that perfectly match each patient’s unique bone structure using FDM PEEK filament technology.

This personalized approach allows you to design complex geometries tailored to individual anatomical requirements, from spinal fusion cages to maxillofacial reconstructions.

PEEK’s biocompatible properties guarantee your custom implants integrate safely with human tissue while providing the mechanical strength needed for load-bearing applications. The material’s mechanical properties closely match those of human bone, making it an ideal substitute for traditional metal implants.

Personalized Implant Design

The rise of personalized orthopedic implants represents a paradigm shift from the one-size-fits-all approach that’s dominated the industry for decades.

You’ll find that computer-assisted design and advanced imaging technologies now enable precise anatomical bone replacement that addresses complex defects and unique patient anatomy.

These customized solutions create complex, free-form interconnected surfaces that improve both fit and functionality while reducing complications from implant-host mismatch. The market for these personalized 3D printed orthopedic implants is experiencing rapid expansion, with projections showing growth to USD 1,779.33 million by 2030.

- Precise anatomical matching through computer-assisted design eliminates standard implant limitations

- Shortened osseointegration time with specially designed trabecular surfaces accelerates healing

- Reduced stress shielding from improved implant conformity prevents bone deterioration

- Lower infection rates possible with advanced surface coatings and better tissue integration

Biocompatible Material Properties

Creating patient-specific orthopedic devices demands materials that seamlessly integrate with human biology while maintaining the mechanical performance required for load-bearing applications.

PEEK’s biological inertness minimizes adverse immune responses while its surface properties encourage cell adhesion and tissue integration. Unlike metal alternatives, you won’t deal with ion release concerns that can compromise long-term biocompatibility.

The material’s elastic modulus closely matches cortical bone, reducing stress shielding and bone resorption risks. You’ll benefit from PEEK’s excellent fatigue resistance for cyclic loading applications and its radiolucent properties that enable clear post-operative imaging.

Surface engineering options like hydroxyapatite or titanium coatings further enhance bioactivity. PEEK’s reduced infection risk through bacterial adhesion resistance and inflammation control makes it ideal for patient-specific orthopedic implementations. The material maintains its biocompatible properties even during autoclave sterilization procedures required for surgical applications.

Downhole Oil Extraction Tools and Equipment

When drilling operations extend thousands of feet below ground, you’ll find PEEK filament becoming an increasingly essential material for manufacturing critical downhole components through FDM 3D printing.

You can produce complex geometries that traditional machining can’t achieve while maintaining the chemical resistance needed for aggressive oil and gas environments. PEEK’s superior performance against corrosion, hydrolysis, and extreme temperatures makes it ideal for these demanding applications. Components like pipe fittings can be printed in approximately three and a half days, enabling rapid deployment for urgent downhole repairs.

- Sealing systems and fasteners that withstand high pressures and corrosive saltwater conditions

- Gas separation systems and drilling tools engineered for extended service life in harsh environments

- Automated production capabilities reducing labor costs through unattended 3D printing processes

- NORSOK M-710 and ISO 23936 compliance ensuring your components meet strict industry standards

Electronic Device Housings for Extreme Environments

Beyond underground drilling environments, PEEK filament proves invaluable for manufacturing electronic device housings that operate in aerospace, military, and industrial settings where failure isn’t an option. You’ll find PEEK’s temperature resistance up to 250°C continuous and 350°C peak exposure makes it perfect for electronics in extreme heat. The material’s superior chemical resistance protects against corrosive environments while maintaining dimensional stability.

| Application | Key Benefit | Temperature Range |

|---|---|---|

| Aerospace Electronics | UV/radiation resistance | -40°C to 250°C |

| Military Communications | Chemical immunity | -55°C to 300°C |

| Marine Sensors | Salt fog resistance | -20°C to 200°C |

| Industrial Controls | Thermal cycling stability | 0°C to 250°C |

You can leverage FDM’s design flexibility to create custom housings with integrated mounting features while reducing weight compared to metal alternatives. The robust construction of specialized filament-making equipment ensures consistent PEEK processing quality for these demanding applications.

Frequently Asked Questions

What Printing Temperatures Are Required for Successful FDM Processing of PEEK Filament?

You’ll need nozzle temperatures between 370°C-420°C, heated bed at 120°C-150°C, and build chamber around 100°C. Don’t forget pre-drying your filament at 120°C for 2-5 hours before printing.

How Does PEEK Filament Compare to Other High-Performance Materials in Cost?

You’ll pay $200-$800 per kg for PEEK filament, making it considerably more expensive than PEKK at €400-500 per kg, specialty filaments under $100 per kg, and standard materials at $15-$60 per kg.

What Post-Processing Techniques Are Recommended for FDM Printed PEEK Components?

You’ll want to use thermal treatment at 150-200°C for 4-12 hours, remove supports carefully, sand for smoothness, and apply protective coatings to enhance PEEK’s mechanical properties and durability.

Which FDM Printer Specifications Are Necessary for Reliable PEEK Filament Printing?

You’ll need a nozzle reaching 370-420°C, heated bed at 120°C minimum, enclosed chamber, reliable thermal control, and heat isolation systems. Your printer must maintain consistent high temperatures throughout extended printing sessions.

How Should PEEK Filament Be Stored to Maintain Optimal Printing Performance?

You’ll need to store PEEK filament in airtight, moisture-barrier bags with desiccants in a cool, dark place. Don’t forget to dry it at 120°C for four hours before printing.

In Summary

You’ll find PEEK filament’s exceptional heat resistance and chemical stability make it essential for these demanding applications. Whether you’re prototyping aerospace components, creating custom medical devices, or developing automotive parts, PEEK’s 260°C continuous service temperature and biocompatibility can’t be matched by standard 3D printing materials. You’re investing in a material that’ll perform reliably in the most extreme industrial environments where failure isn’t an option.

Leave a Reply