You’ll need to understand five critical safety standards when selecting flame retardant filaments for 3D printing. UL 94 V-0 provides the highest flammability rating, requiring self-extinguishing within 10 seconds. FAR 25.853 governs aviation materials through vertical burn tests. UL 60950-1 guarantees electronic equipment fire safety. TSCA regulates chemical compliance for flame retardant additives. Temperature resistance testing protocols assess structural integrity post-burn. These standards guide your material selection for specific industry applications and compliance requirements.

UL 94 V-0 Classification Requirements for 3D Printing Materials

When you’re selecting 3D printing materials for safety-critical applications, UL 94 V-0 represents the gold standard for flame resistance. This highest flammability rating requires materials to self-extinguish within 10 seconds after flame removal, with no flaming drips allowed.

You’ll find certification involves rigorous testing by Underwriters Laboratories, where materials face two 10-second flame exposures.

For 3D printing, you can choose from several UL 94 V-0 certified options including ULTEM 9085, Cubicure Evolution FR, and Formlabs Flame Retardant Resin.

These materials meet strict requirements for electronics, transportation, and medical device applications. However, you’ll need to take into account that flame retardant additives can alter mechanical properties and increase costs while adding manufacturing complexity to your projects. Keep in mind that part thickness can significantly impact your UL rating outcomes during the certification process.

FAR 25.853 Aviation Standards for Aerospace Applications

Beyond commercial flammability standards, you’ll encounter FAR 25.853 when working with aerospace applications—a Federal Aviation Regulation that sets the benchmark for aircraft interior material safety.

This regulation governs both cabin and cargo compartments through rigorous testing protocols, including the vertical Bunsen burner test where materials face either 60-second or 12-second flame exposure.

You’ll need at least three test samples, and results depend on flame time, ignition time, burn length, and drip flame time criteria.

The standard evaluates fire resistance, heat release, smoke density, and toxicity properties.

Materials like TUFFAK FI and LF polycarbonate sheets meet these requirements.

FAR 25.853’s global adoption guarantees consistent aerospace fire safety standards across manufacturers worldwide. The F.I.R.S.T. principle provides a comprehensive framework for evaluating aircraft material fire performance across flame spread, ignitability, rate of heat release, smoke density, and toxicity characteristics.

UL 60950-1 Electronic Equipment Fire Safety Specifications

While aerospace applications demand FAR 25.853 compliance, electronic equipment manufacturers must navigate UL 60950-1 specifications to confirm fire safety in information technology devices.

You’ll need to verify your equipment reduces risks of fire, electric shock, and injury for both operators and users. This standard applies broadly to telecommunication terminals, network infrastructure, data processing equipment, and power supplies.

Your equipment must pass rigorous testing under normal and fault conditions, including:

- Temperature, altitude, and pollution exposure scenarios

- Overvoltage conditions from mains and telecom networks

- Fire-resistant material and enclosure requirements

- Quality control measures throughout manufacturing

Remember that complete IT equipment must achieve full compliance, even if individual components don’t meet every specification independently. The standard covers equipment with rated voltage not exceeding 600 V designed for installation per Canadian and National Electrical Codes.

Proper certification confirms your products meet these critical safety standards.

TSCA Chemical Compliance for Flame Retardant Additives

As manufacturers incorporate flame retardant additives into their products, they must navigate the complex requirements of the Toxic Substances Control Act (TSCA), which grants the EPA authority to regulate chemical substances throughout their lifecycle.

You’ll need to verify your flame retardant additives comply with current restrictions. The EPA has banned certain chemicals like DecaBDE and PIP(3:1) in non-medical products, with compliance deadlines already in effect. You’re required to reformulate products containing these restricted substances and adjust your supply chains accordingly.

The EPA regulates these substances under TSCA’s PBT Chemicals section, which specifically targets persistent, bioaccumulative, and toxic chemicals that pose environmental and health risks.

| Compliance Requirement | Action Needed |

|---|---|

| Restricted Chemicals | Remove DecaBDE and PIP(3:1) from products |

| Compliance Timeline | Meet EPA-mandated deadlines |

| Alternative Development | Research safer flame retardant options |

| Reporting Obligations | Document chemical usage and substitutions |

Non-compliance can result in significant penalties, making adherence essential for your business operations.

Temperature Resistance and Structural Integrity Testing Protocols

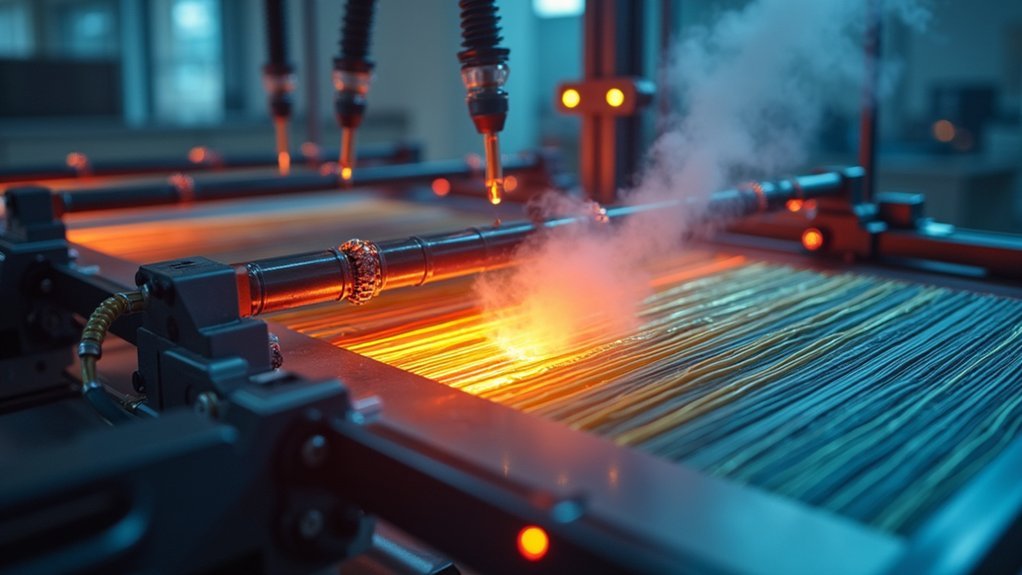

When evaluating flame retardant filaments for critical applications, you must subject them to rigorous temperature resistance and structural integrity testing protocols that determine their performance under extreme thermal conditions.

These thorough assessments guarantee your materials won’t compromise safety when exposed to fire.

Your testing regimen should include:

- UL 94 standard testing – Burn specimens over two consecutive 10-second periods to assess flame retardancy and extinguishing capabilities

- Thermal analysis techniques – Use TMA and DSC methods to evaluate thermal stability and material changes under high temperatures

- Post-burn structural assessment – Analyze material deformation, residual mechanical strength, and char formation after fire exposure

- Vertical burn tests – Follow CS 25.853 guidelines to evaluate flammability and structural integrity under controlled environmental conditions

You’ll need standardized sample preparation and consistent protocols to account for material batch variability. Performance characteristics can change significantly with specimen thickness, as thicker samples demonstrate increased resistance to ignition during standardized testing procedures.

Frequently Asked Questions

What Are the Typical Costs Associated With Flame Retardant Filament Certification?

You’ll face certification fees ranging from hundreds to thousands of dollars, plus testing costs, documentation expenses, and periodic renewal fees. Costs vary considerably based on standards like UL94 V-0 versus V-2 requirements.

How Long Do Flame Retardant Certifications Remain Valid Before Renewal?

Your flame retardant certifications typically remain valid for one to three years, depending on the standard. UL 94 stays valid until you change materials, while FDNY C-15 requires renewal every three years.

Can Flame Retardant Filaments Be Recycled After Use?

You can recycle flame retardant filaments, but it’s challenging due to complex additives and limited infrastructure. The recycling process requires specialized segregation and technology that’s still developing economically.

What Health Risks Are Associated With Printing Flame Retardant Materials?

You’re exposed to toxic chemicals that your skin can absorb, plus harmful airborne particles and VOCs that cause respiratory issues, cancer risks, and hormone disruption when printing flame retardant materials.

Which Industries Have Mandatory Flame Retardant Requirements Versus Voluntary Standards?

You’ll find mandatory flame retardant requirements in automotive, aerospace, construction, and maritime industries due to strict safety regulations, while consumer products, textiles, and electronics typically follow voluntary standards.

In Summary

You’ll need to verify your flame retardant filaments meet these five critical safety standards before using them in professional applications. Don’t compromise on UL 94 V-0 ratings for general use, FAR 25.853 compliance for aerospace projects, or UL 60950-1 requirements for electronics. You’re also responsible for ensuring TSCA chemical compliance and conducting proper temperature resistance testing. These standards aren’t optional—they’re essential for protecting lives and meeting industry regulations.

Leave a Reply