You’ll need three essential methods to maintain precise filament diameter control in your production line. Digital calipers offer cost-effective spot checks with 0.01mm resolution for routine quality verification. Laser micrometers provide continuous non-contact monitoring using optical beams, with dual-axis models detecting ovality around $2600. Three-axis monitoring devices deliver complete dimensional analysis across X, Y, and Z planes for superior irregularity detection. Each method integrates with control systems for automated feedback, and understanding their specific applications will optimize your quality control strategy.

Digital Caliper Measurement for Routine Quality Checks

When implementing routine quality control for filament production, digital calipers serve as your most accessible and cost-effective measurement tool.

You’ll find resolutions ranging from 0.01mm to 0.1mm sufficient for standard quality checks, though they’re less precise than micrometers for critical measurements.

You must apply consistent pressure when measuring to avoid deforming the filament and guarantee repeatable results.

Temperature and humidity changes can affect accuracy, so you’ll need periodic calibration.

The user-friendly digital interface eliminates reading errors, while some models connect directly to Arduino boards for automated data logging.

For recycling projects converting 3mm to 1.75mm filament or maintaining 3D printing consistency, digital calipers provide adequate precision.

They’re particularly valuable for quick diameter verification during production runs. Digital calipers operate through capacitance measurement between internal copper pads, with a microcontroller counting capacitance peaks to determine precise distances.

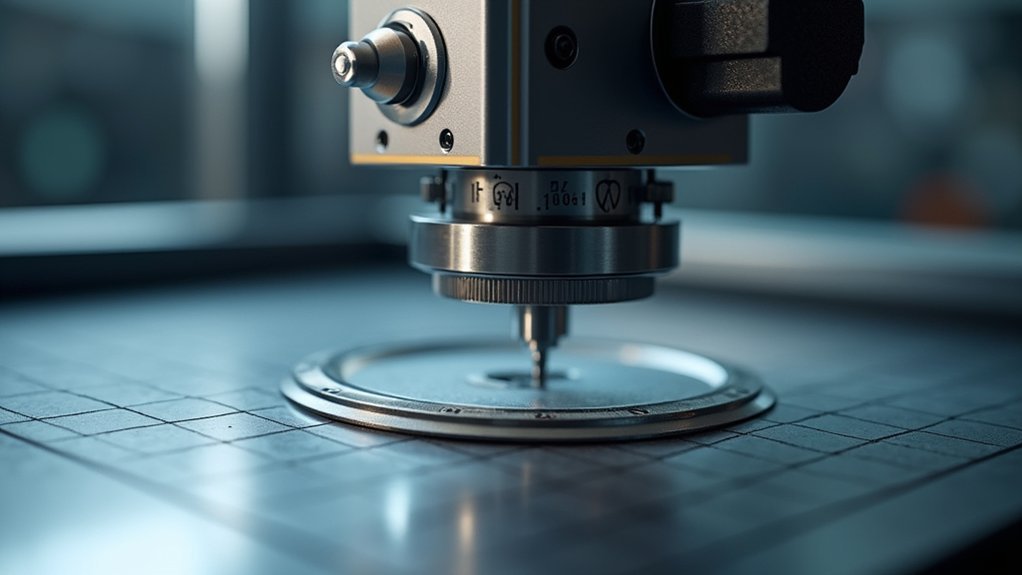

Laser Micrometer Systems for Continuous High-Precision Monitoring

For continuous high-precision monitoring of filament diameter, laser micrometer systems represent the industry standard for automated quality control.

You’ll benefit from non-contact measurement that prevents filament distortion while maintaining exceptional accuracy. These systems use rotating optical beams that create shadows when interrupted by your filament, allowing real-time diameter monitoring.

Non-contact optical measurement eliminates filament distortion while delivering exceptional accuracy through rotating laser beams and real-time shadow detection.

Dual-axis models measure X and Y diameters simultaneously, detecting ovality and irregularities from multiple angles. You can integrate these systems with PLCs using MODBUS protocols for automated feedback control to your extruders.

Operating within -10 to 40°C temperature ranges, they’re ideal for fragile or moving filaments. Advanced systems feature telecentric lenses that ensure measurement accuracy even when filaments are misaligned during production.

While basic dual-axis models cost around $2600, they’ll reduce material waste and improve product quality through precise, continuous monitoring without physical contact interference.

Three-Axis Monitoring Devices for Complete Dimensional Analysis

Three-axis monitoring devices advance beyond dual-axis laser micrometers by analyzing your filament’s complete dimensional profile across X, Y, and Z axes simultaneously.

You’ll achieve superior accuracy when detecting irregularities and defects compared to traditional one-dimensional sensors. These systems require precise alignment and calibration across all axes, but they’ll provide thorough data on your filament’s surface structure and dimensional consistency.

You can customize these devices for different manufacturing environments and materials, making them versatile for various polymer types. They’ll integrate with your existing control systems to automatically adjust production parameters.

While initial setup costs are significant, you’ll reduce long-term expenses by eliminating multiple single-axis sensors. The automated inspection process increases your production efficiency while providing detailed measurement history for quality documentation and process optimization. Open-source alternatives utilizing mirror-based optics can significantly reduce equipment costs while maintaining measurement accuracy for smaller operations.

Frequently Asked Questions

How Often Should Filament Diameter Measurements Be Taken During Production?

You should take filament diameter measurements multiple times per second during production. This high frequency enables real-time quality control, immediate adjustments, and prevents undetected deviations that’ll affect print quality.

What Happens to Print Quality When Filament Exceeds Specified Tolerance Limits?

When your filament exceeds tolerance limits, you’ll experience over-extrusion or under-extrusion, creating poor surface finish, dimensional inaccuracy, weakened structural integrity, potential nozzle clogging, and increased material waste during printing.

Can Diameter Variations Be Corrected Automatically During the Printing Process?

You can correct diameter variations automatically using real-time monitoring systems like Qu-Control that measure filament continuously and adjust extrusion flow instantly, or AI-driven calibration that detects inconsistencies during printing.

What Tolerance Range Is Considered Acceptable for Professional 3D Printing Applications?

You’ll find that ±0.05 mm around nominal diameter is typically acceptable for professional applications, though higher-quality filaments achieve stricter ±0.02 mm tolerances for markedly improved print consistency and precision.

How Much Does Filament Diameter Affect the Volume of Extruded Material?

Filament diameter dramatically affects extrusion volume through the squared relationship of cross-sectional area. You’ll see a 10% diameter increase creates roughly 21% more material output, greatly impacting your print quality and material consumption.

In Summary

You’ll achieve consistent 3D printing results by implementing these three quality control methods strategically. Use digital calipers for quick spot checks during production runs, install laser micrometers for real-time monitoring of critical filaments, and deploy three-axis systems when you need complete dimensional validation. Don’t rely on just one method—combine them based on your quality requirements and budget. Consistent diameter control directly translates to better print quality and fewer failed prints.

Leave a Reply