You’ll want to evaluate the COBOD BOD2, which leads the market with over 50 global deployments and fits in standard shipping containers for easy transport. The MaxiPrinter by Constructions-3D offers dual electric-diesel power capability and extensive French training programs. MudBots Gantry excels with over 100 tested mix recipes and compressive strengths up to 10,000 PSI. Each system prints at 250 mm/s with a 12.5-meter reach, though their specific advantages for different project requirements deserve closer examination.

COBOD BOD2 3D Construction Printer

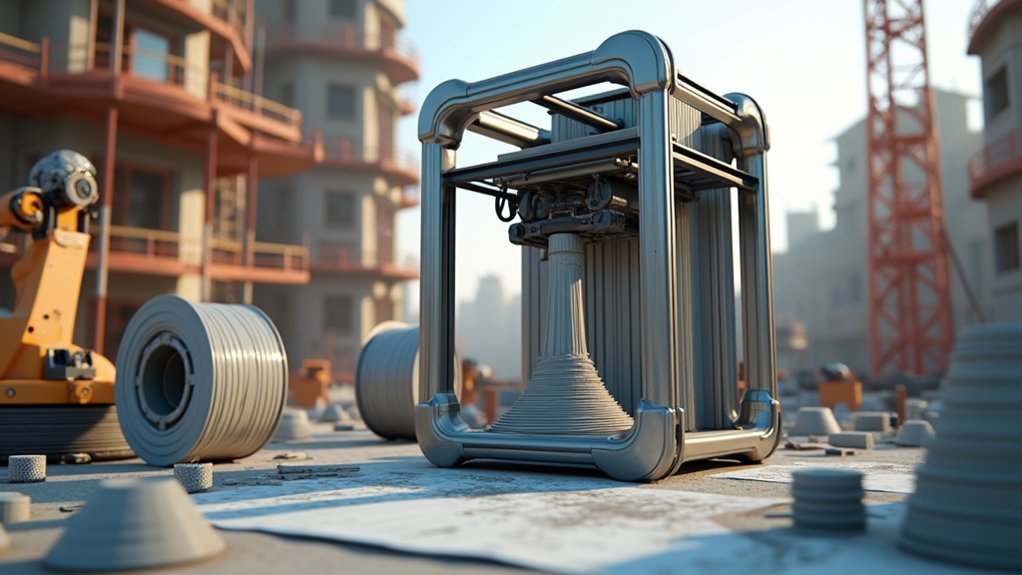

When you’re looking for proven 3D construction printing technology, the COBOD BOD2 stands out as the world’s most widely adopted solution with over 50 units deployed across global construction sites.

This printer delivers impressive capabilities with its 12.5-meter maximum printable length and 150 square meter print area, allowing you to tackle large-scale construction projects efficiently.

You’ll benefit from its remarkable 250 mm/s print speed and factory-calibrated precision that guarantees accurate concrete printing technology applications.

The energy efficient design features a foldable frame that fits in a standard 20-foot container, making transportation seamless across diverse terrains.

You can utilize various pumpable printing materials while supporting multiple printers simultaneously, revolutionizing how the construction industry approaches 3D printed structures and enhancing overall production efficiency.

MaxiPrinter Concrete 3D Printer by Constructions-3D

Precision meets versatility in the MaxiPrinter Concrete 3D Printer by Constructions-3D, delivering the same impressive 12.5-meter maximum printable length and 150 square meter print area as leading competitors while offering unique dual-power capabilities.

This concrete printer operates on both electric and diesel power, adapting to any construction environment. You’ll achieve construction printing speeds up to 250 mm/s while maintaining factory-calibrated accuracy for complex 3D printed structures.

The MaxiPrinter’s mobility advantage lets you speed up construction across multiple sites. At 2700 kg and 86 cm wide, it transports easily in standard containers.

Your purchase includes week-long training in France, ongoing maintenance support, and CAD software compatibility. Whether you’re creating vertical walls or urban furniture, this printing process optimizes material cost and efficiency.

Join us in revolutionizing how you print structures.

MudBots Gantry 3D Concrete Printer

Large-scale construction projects demand equipment that can handle substantial structures without compromising precision, and the MudBots Gantry 3D Concrete Printer delivers exactly that capability. This advanced concrete 3D printing system eliminates traditional construction framing methods while processing CAD files into precise 3D models for seamless execution.

| Feature | Capability | Benefit |

|---|---|---|

| Mix Formulas | 100+ tested recipes | Ideal fluidity/strength |

| Compressive Strengths | 1200-10,000 PSI range | Versatile applications |

| Installation Integration | Real-time electrical/plumbing | Streamlined workflow |

| Environmental Adaptation | On-site batching adjustments | Weather-responsive mixing |

You’ll benefit from thorough training programs that include hands-on experience, ensuring effective operation and maintenance. The on-site batching feature allows real-time concrete adjustments based on environmental conditions, greatly improving construction efficiency compared to traditional methods.

Frequently Asked Questions

What Is the Best Type of 3D Printing for Construction?

You’ll find concrete 3D printing’s the best choice for construction. It lets you create structures without traditional framing, prints complex shapes quickly, and reduces your labor costs while allowing real-time design adjustments.

How Much Does a Construction 3D Printer Cost?

You’ll spend around $570,000 for a MaxiPrinter, though construction 3D printer costs vary widely by specifications and brand. Don’t forget additional expenses like training, support, and maintenance when budgeting.

What Is the Most Profitable Thing to Make With a 3D Printer?

You’ll find custom architectural elements most profitable since they’re high-demand with little competition. Bespoke prototypes for medical or consumer products also generate premium rates due to rapid customization capabilities.

What Is the 45 Degree Rule for 3D Printing?

You should keep overhangs at 45 degrees or less when 3D printing. This prevents sagging and collapse, reduces support material needs, and guarantees better layer adhesion for stronger, higher-quality prints.

Leave a Reply