Large-scale 3D printing for construction components uses additive manufacturing to create building elements like walls, foundations, and complex structures measuring several meters directly on-site. You’ll reduce construction timelines from weeks to hours while cutting material waste by 60% and labor costs by 80%. The technology utilizes concrete, mortar, and geo polymers through CAD-guided robotic systems and gantry printers. This innovation transforms traditional construction methods, enabling sustainable practices and enhanced structural integrity. Continue exploring to discover specific applications reshaping modern architecture.

What Is Large-Scale 3D Printing for Construction Components?

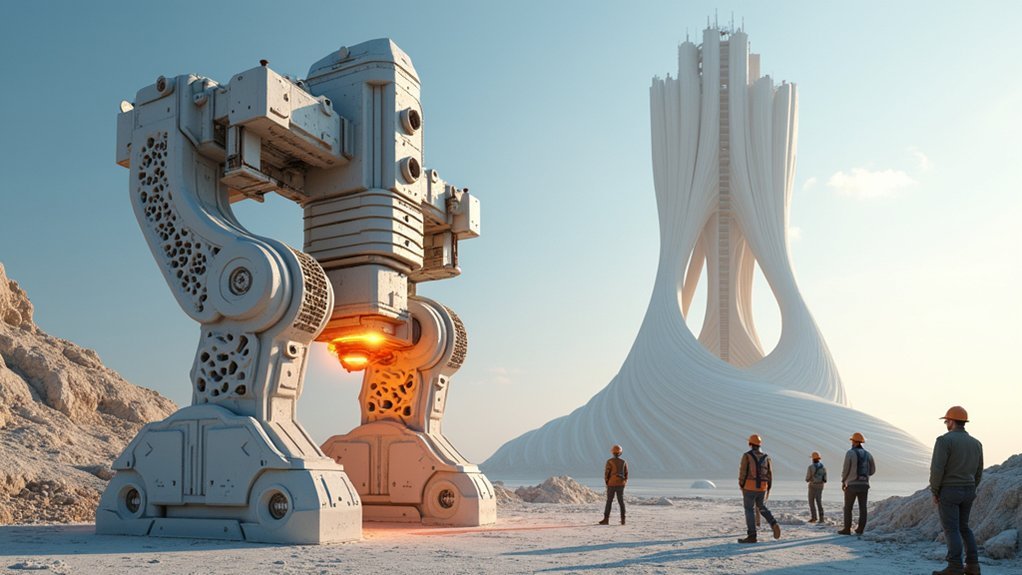

Innovation in construction technology has reached a pivotal moment with large-scale 3D printing, which uses additive manufacturing to create building components and entire structures from materials like concrete.

You’ll find this concrete printing technology revolutionizes how the construction industry approaches large projects by enabling efficient production of complex structures with dimensions reaching several meters.

Unlike traditional construction methods, you can now produce intricate architectural designs without extensive assembly requirements. This rapid prototyping capability dramatically reduces construction timelines, allowing you to complete projects in hours rather than weeks.

The technology minimizes material waste by up to 60%, making your building processes more sustainable. Large scale 3D printing eliminates many structural weak points while maintaining design flexibility for your construction needs.

Benefits of Large-Format Construction 3D Printing

As construction companies adopt large-format 3D printing technology, you’ll discover transformative advantages that reshape how building projects operate from conception to completion.

Large scale 3D printers reduce material waste by up to 60%, supporting sustainable building practices while cutting costs. You’ll see dramatic improvements in project timelines, completing structures in days rather than months.

Large-scale 3D printing cuts material waste by 60% while completing construction projects in days instead of months.

Construction printing enhances structural integrity by creating components in single pieces, eliminating weak assembly joints. Through automation, you’ll slash labor costs by 80% while improving worker safety.

The technology’s rapid market growth from $190 million in 2021 to a projected $680 million by 2030 demonstrates its increasing value in modern construction.

Materials and Technologies Used in Construction-Scale Printing

These remarkable benefits stem directly from the advanced materials and sophisticated technologies that power construction-scale 3D printing systems. You’ll find concrete, mortar, and various pumpable materials at the core of large construction applications, enabling monolithic structures without traditional formwork. The additive manufacturing process layers materials precisely using CAD-guided printing methods.

| Technology Type | Key Features |

|---|---|

| Robotic Arms | Flexible complex geometry printing |

| Gantry Systems | Large-scale component fabrication |

| Concrete Mixtures | Primary construction materials |

| Geo Polymers | Sustainable innovative alternatives |

You can leverage these 3D printing technologies for diverse applications, from residential buildings to infrastructure components. The market’s projected growth from $190 million to $680 million by 2030 reflects increasing adoption of these materials and manufacturing techniques in construction.

Types of Large-Scale Construction 3D Printers

You’ll find that mobile concrete printers offer exceptional versatility for on-site construction projects, allowing you to move equipment directly to where it’s needed most.

These systems come with large format capabilities that exceed 1000mm in multiple axes, enabling you to print substantial architectural components in single pieces.

You can choose from various power source options to match your specific site requirements and operational constraints.

Mobile Concrete Printers

Mobile concrete printers represent one of the most versatile solutions in large-scale construction 3D printing, offering contractors the flexibility to bring advanced manufacturing directly to job sites.

You’ll find these systems, like the MaxiPrinter, fit into standard 20-foot shipping containers for easy transport across diverse terrains.

These mobile units excel at creating large-scale structures with impressive capabilities:

- Speed and efficiency: Achieve printing speeds up to 250 mm/s while reducing construction time compared to traditional methods

- Versatile applications: Print walls, poles, and urban furniture using specialized concrete and pumpable 3D printing materials

- Quick deployment: Set up in under 15 minutes with electric or diesel power options

You’ll eliminate formwork requirements and minimize waste while accessing remote locations that fixed printers can’t reach.

Large Format Capabilities

Beyond their mobility advantages, large format 3D printers distinguish themselves through their extensive build volumes that exceed 1000mm in one or more axes, enabling you to construct substantial building components as single, unified pieces.

You’ll find two primary types dominating large-scale construction applications: robotic arms and gantry systems. Robotic arms offer exceptional flexibility for creating complex geometries and intricate architectural designs, while gantry systems excel at contouring methods for larger prints.

Most large format printers utilize the extrusion method, where materials are layered through nozzles to form structures.

You can work with diverse materials including concrete, mortar, and specialty composites. This versatility in materials enhances your ability to create robust, sustainable construction components tailored to specific project requirements.

Power Source Options

When selecting a large-scale construction 3D printer, you’ll encounter flexible power source options that adapt to diverse job site conditions.

Modern printers like the MaxiPrinter offer both electric and diesel configurations, guaranteeing you’re covered whether working on remote locations or urban construction sites.

These versatile machines provide significant advantages:

- Electric power delivers clean, quiet operation perfect for urban environments with strict noise regulations

- Diesel engines enable autonomous operation in remote areas without reliable electrical infrastructure

- Quick deployment allows 15-minute operational setup time regardless of your chosen power source

You’ll appreciate how these printers can be easily transported in standard 20-foot containers between projects.

The low 200 cm deployed height ensures accessibility across various terrains, making large scale construction printing viable anywhere you need it.

The Construction 3D Printing Process

Five distinct phases define the construction 3D printing process, each requiring precise execution to transform digital blueprints into physical structures.

You’ll begin with Design & Modeling, creating digital 3D models using CAD software or BIM tools that serve as your project’s foundation.

Next, you’ll slice these models into printable layers, ensuring your printer’s compatibility for accurate material deposition.

During Printer Setup, you’ll calibrate your machine and load the specific construction material required for your project.

The Printing phase follows, where material gets deposited layer by layer through specialized nozzles, building your structure according to design specifications.

Finally, you’ll conduct Quality Inspection, evaluating the completed structure for defects and verifying it meets your original design requirements before accepting the finished product.

Applications and Real-World Examples

Three major sectors are driving the adoption of large-scale 3D printing in construction: residential housing, commercial buildings, and infrastructure projects.

Construction’s future lies in three transformative sectors: residential housing, commercial buildings, and infrastructure projects embracing large-scale 3D printing technology.

You’ll find this technology excels in applications that require complex parts and rapid construction time across diverse production applications.

- Residential Projects: In Wapakoneta, OH, you can see the first 3D-printed home designed for fire and tornado resistance, proving that printing materials used in 3D printing deliver exceptional durability for housing solutions.

- Commercial Developments: The 3D-printed Walmart Supercenter expansion in Athens, TN spans 8,000 square feet, while Florida’s Printed Farms Luxury Equestrian Facility reaches 10,105 square feet as the world’s largest structure.

- Infrastructure Solutions: Miami’s 3D-printed seawalls combat rising sea levels, demonstrating how this technology continues advancing large parts manufacturing for environmental protection.

Future Developments in Large-Scale Construction Printing

Where will large-scale construction printing head next?

You’ll see remarkable growth as the printing in construction market expands from $190 million to $1.03 billion by 2028.

You can expect enhanced material diversity incorporating local natural resources and waste materials, driving sustainability forward.

Large scale projects will benefit from dramatically improved printing speeds, completing structures in hours rather than months.

Your design-to-construction workflow will become more streamlined through advanced CAD and BIM integration, boosting accuracy and efficiency.

You’ll witness ongoing research addressing machinery costs and material properties, paving the way for widespread urban construction adoption.

These developments position you to transform how buildings are conceived, designed, and constructed in tomorrow’s cities.

Frequently Asked Questions

What Is the Best Type of 3D Printing for Construction?

You’ll find extrusion-based 3D printing works best for construction since it’s efficient and precise. However, you should choose robotic arms for complex designs or gantry systems for larger projects based on your specific requirements.

How Much Does a Large-Scale 3D Printer Cost?

You’ll pay around $570,000 for a basic large-scale 3D printer, though advanced models exceed $1 million. Don’t forget additional costs like maintenance support, operator training, and delivery expenses when budgeting.

How Much Does a Construction 3D Maxi Printer Cost?

You’ll pay $570,000 for the MaxiPrinter Concrete 3D Printer’s starting price. However, you should budget more since costs increase with additional features, training, and support options you choose during purchase.

Can 3D Printing Be Used in Construction?

You can definitely use 3D printing in construction to build walls, poles, and furniture. It’ll reduce your material waste by 60% and cut labor costs by 80% through automated layering processes.

Leave a Reply