To 3D print custom brake caliper covers, start by measuring your existing calipers and creating digital models using CAD software. You’ll need heat-resistant materials like ABS or nylon since brake components generate significant heat. Set your printer to 0.1-0.2mm layer height with temperatures around 210-250°C for strong layer adhesion. Print slowly at 40-60mm/s with minimal cooling to prevent warping. After printing, verify proper fit before installation. This guide covers everything you’ll need for professional-quality results.

Designing Your Custom Brake Caliper Covers

Anyone can transform their vehicle’s appearance by designing custom brake caliper covers that perfectly match their style preferences.

Start by sketching your design ideas, focusing on aesthetics while guaranteeing dimensions fit your specific brake caliper model. You’ll need to measure your existing calipers carefully to create accurate templates.

Measure your brake calipers precisely and sketch design concepts that balance visual appeal with exact dimensional requirements for proper fitment.

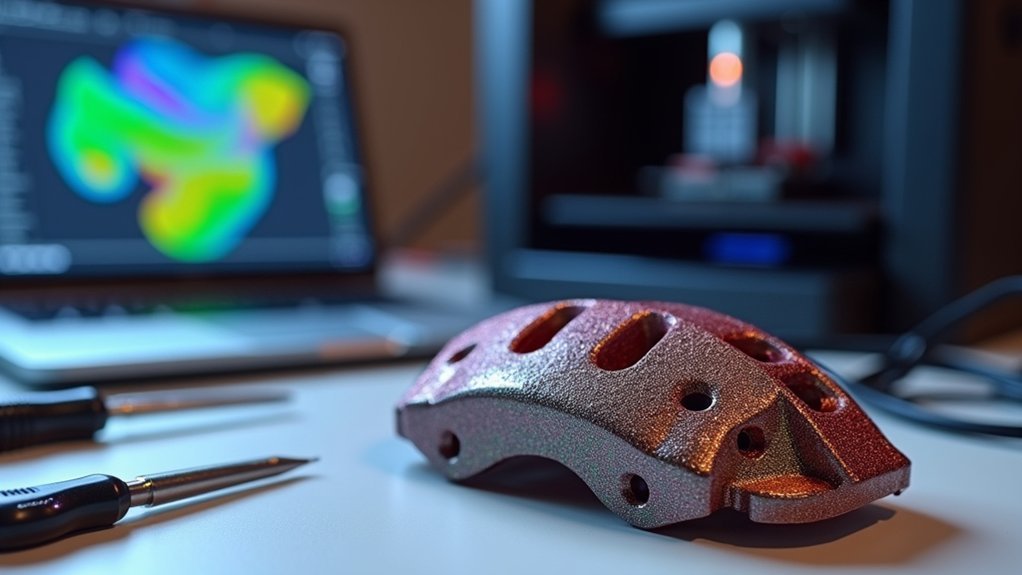

Once you’ve finalized your concept, use 3D modeling software like CAD or Blender to create precise digital models.

Pay close attention to fit and clearance around brake components – your brake caliper cover mustn’t interfere with moving parts or heat dissipation.

Consider incorporating ventilation slots or decorative elements that complement your vehicle’s styling.

Remember to account for mounting points and hardware during the design phase to guarantee secure attachment.

Selecting the Right Materials and Filament Types

What filament will withstand the intense heat and stress that brake systems generate?

You’ll need materials that won’t deform or crack under extreme conditions. ABS stands out as your best choice for brake calipers due to its exceptional durability and heat resistance, making it ideal for automotive applications.

While PLA’s easier to print, it lacks the necessary temperature tolerance for this demanding environment.

Nylon filaments offer excellent strength and flexibility, perfect when you need impact resistance.

PETG provides another solid option with strong mechanical properties and good temperature resistance that’ll handle brake system heat without warping.

- Steam rising from hot brake rotors after aggressive driving

- Melted plastic dripping from failed caliper covers

- Cracked covers scattered on your garage floor

Always verify manufacturer specifications for heat resistance before printing.

Preparing Your 3D Printer and Slicing Settings

With your material selected, you’ll need to configure your 3D printer and enhance slicing settings for automotive-grade results.

Start by calibrating your printer properly, guaranteeing bed leveling and correct nozzle height to prevent adhesion failures that could ruin your caliper covers.

In your slicing software, set layer height between 0.1-0.2 mm for ideal detail capture.

Adjust print temperature according to your filament specifications—typically 210-250°C for ABS—to achieve strong layer bonding.

Configure infill density and print speed based on your design’s structural requirements.

Enable supports for any overhangs in your caliper cover design, and add a brim to improve first-layer stability.

These settings guarantee your covers maintain dimensional accuracy and structural integrity for automotive applications.

Printing Process and Quality Control Tips

You’ll achieve professional-quality brake caliper covers by focusing on two critical aspects during and after printing.

First, optimize layer adhesion by maintaining consistent bed temperature and monitoring your first few layers to prevent warping that could compromise the cover’s structural integrity.

Second, plan for post-processing surface finishing techniques like sanding and acetone vapor smoothing to eliminate layer lines and create the smooth, professional appearance your custom covers deserve.

Layer Adhesion Optimization

Since layer adhesion determines whether your brake caliper covers will withstand the heat and vibration of automotive environments, you’ll need to dial in your printer’s temperature settings with precision.

For ABS filament, maintain extruder temperatures between 200-220°C to guarantee proper interlayer bonding. Set your heated bed to 80-100°C to prevent lifting and warping throughout the print process.

Slow down your print speed to 40-60 mm/s, giving each layer adequate time to bond before applying the next. Use minimal cooling fan settings to maintain layer integrity while preventing rapid temperature drops that cause delamination.

- Steam rising from molten plastic as layers fuse into solid automotive-grade components

- Glass-smooth brake caliper covers bonding layer by layer under controlled heat

- Precision nozzle depositing consistent filament streams at ideal temperatures for maximum layer adhesion optimization

Post-Processing Surface Finishing

Perfect layer adhesion sets the foundation, but raw 3D printed brake caliper covers require strategic post-processing to achieve professional-grade results.

Start by inspecting your custom brake caliper covers for warping or defects before proceeding. Sand all surfaces thoroughly to eliminate layer lines and create smooth finishes that enhance aesthetic appeal and paint adhesion.

For ABS materials, consider vapor smoothing with solvents to reduce surface roughness and achieve a polished appearance.

Apply primer coats to establish uniform bases that improve finish durability. After painting your custom brake caliper covers, add clear coats for additional protection against heat and environmental factors.

This multi-step approach guarantees your covers maintain visual integrity and longevity while delivering professional-quality results that rival commercial alternatives.

Post-Processing and Finishing Techniques

Transforming your freshly printed brake caliper covers from rough prototypes into professional-looking components requires strategic post-processing techniques.

Start by sanding away layer lines with progressively finer grits to achieve smooth surfaces. For ABS prints, vapor smoothing with acetone creates an impressive glossy finish that’ll tell us you’re serious about quality.

Heat treatment strengthens ABS materials, making your covers more resistant to brake-generated temperatures.

Apply primer before painting to guarantee better adhesion and color vibrancy. Complete the process with a clear protective coat that guards against scratches, UV damage, and chemical exposure.

- Acetone vapor creating mirror-like surfaces on previously rough plastic

- Layer lines disappearing under careful sanding motions

- Vibrant paint colors emerging through proper primer application

Installation and Mounting Your Custom Covers

After completing your post-processing work, you’ll need to verify your custom covers match your brake caliper dimensions precisely—typically 19.30 x 5.10 x 4.00 cm for compact vehicles or 24.50 x 6.50 x 4.00 cm for larger models.

Start by thoroughly cleaning your brake calipers to remove dirt and grease, guaranteeing better adhesion and proper fit. Since you’ve used durable ABS material, your covers will withstand heat and maintain their shape during installation.

Most custom covers feature tool-free mounting designs for straightforward setup. Follow your installation instructions carefully during mounting.

Once installed, check for movement or looseness to confirm the covers are properly secured. This final inspection prevents potential damage during vehicle operation and guarantees your custom brake caliper covers perform reliably.

Frequently Asked Questions

Can You 3D Print Calipers?

You can 3D print calipers using durable materials like ABS or nylon. Advanced techniques with titanium powder create high-performance parts that withstand extreme temperatures and offer customization impossible with traditional manufacturing methods.

What Are You Not Allowed to 3D Print?

You can’t 3D print patented items, firearms, counterfeit products, or dangerous materials. Lock-picking tools and burglary aids are also prohibited. These restrictions protect intellectual property, public safety, and prevent illegal activities across most jurisdictions.

What Material Are Brake Caliper Covers Made Of?

You’ll find brake caliper covers are typically made from ABS plastic, which offers excellent heat and impact resistance. Some manufacturers also use polycarbonate or nylon for superior durability and environmental protection.

Is It Safe to 3D Print Car Parts?

You can safely 3D print car parts if you’re using quality materials like ABS or nylon, ensuring proper specifications, and testing them under realistic stress and temperature conditions before installation.

Leave a Reply