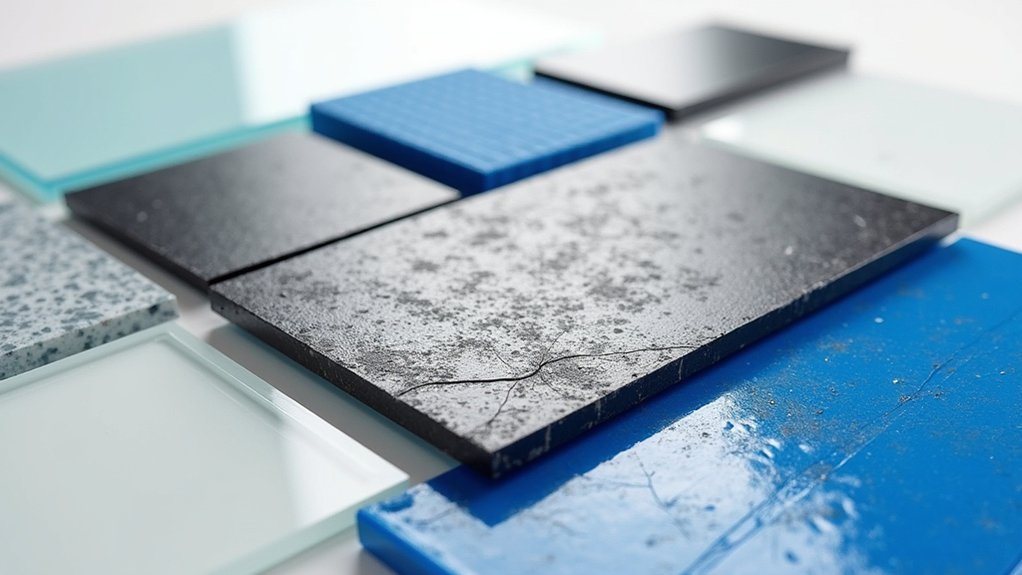

You’ve probably experienced the frustration of prints warping, sticking too well, or failing to adhere properly to your build surface. The right material can make or break your 3D printing success, but with countless options flooding the market, choosing one that’ll actually withstand months of heavy use isn’t straightforward. Some materials promise durability yet crack after weeks, while others excel in longevity but compromise print quality. The key lies in understanding which surfaces truly deliver on both fronts.

Luminate 3D Printer Build Surface Plate Upgrade (254x235x2) G10 Garolite

If you’re seeking a build surface that eliminates the frustration of warped prints and inconsistent adhesion, the Luminate G10 Garolite plate delivers exceptional durability for demanding 3D printing projects. This 254x235x2mm upgrade fits Prusa i3 MK3/S/+, Raise3D N1, and VORON Switchwire printers perfectly.

You’ll experience excellent first layer adhesion with effortless print removal, maintaining intricate details without warping. The 2mm thickness provides ideal rigidity while resisting thermal expansion and harsh chemicals.

Regular maintenance involves cleaning with soap, water, and alcohol. For extended use, wet sand with 600-grit sandpaper to restore adhesion properties, especially when printing ABS materials consistently.

Best For: 3D printing enthusiasts with Prusa i3 MK3/S/+, Raise3D N1, or VORON Switchwire printers who want superior adhesion and print quality without the hassle of warped prints or difficult print removal.

Pros:

- Excellent first layer adhesion with effortless print removal that preserves intricate details without warping

- Exceptional durability with resistance to high temperatures and harsh chemicals for long-lasting performance

- Optimal 2mm thickness provides rigidity while minimizing thermal expansion for consistent print quality

Cons:

- Adhesion may decrease after extended use, requiring wet sanding and cleaning maintenance

- Excessive adhesion when printing with TPU materials can cause difficulties

- Some users may need to explore alternative options depending on specific material requirements

FLASHFORGE PLA Filament 1.75mm Galaxy Matte Black (1kg Spool)

FLASHFORGE’s Galaxy Matte Black PLA filament stands out as the ideal choice for creators who want their prints to catch the eye with its distinctive silver glitter effect. You’ll achieve best results using a nozzle of 0.6mm or larger to accommodate the glitter particles. The filament’s low melting point of 170°C to 180°C guarantees compatibility with most printers while reducing warping risks. You won’t deal with unpleasant odors during printing sessions, making it perfect for home or office environments. Each spool comes vacuum-sealed after 24-hour drying, preventing clogs and guaranteeing smooth feeding with precise 1.75mm diameter tolerance.

Best For: 3D printing enthusiasts and creators who want eye-catching prints with a unique shimmering effect for decorative items, artistic projects, or anything that benefits from a distinctive metallic sparkle finish.

Pros:

- Contains silver glitter particles that create a unique shimmering effect, making prints visually striking and distinctive

- Low printing temperature (170°C-180°C) with minimal warping ensures compatibility with most printers and stable results on large projects

- Vacuum-sealed after 24-hour drying process with precise diameter tolerance prevents clogs and ensures smooth, reliable printing

Cons:

- Requires nozzle size of 0.6mm or larger to accommodate glitter particles, limiting compatibility with standard 0.4mm nozzles

- Glitter content may cause faster nozzle wear compared to standard PLA filaments

- Higher cost compared to regular PLA filaments due to specialty glitter additive

Gizmo Dorks PEI Sheet 3D Printer Build Surface for Creality Ender 3 or CR 20

Creality Ender 3 and CR 20 owners who want a premium build surface upgrade will find the Gizmo Dorks PEI Sheet delivers exceptional durability and performance. This USA-made 235mm x 235mm Ultem 1000 PEI surface features preapplied 3M 468MP adhesive for bubble-free installation. You’ll get excellent adhesion at 60°C for PLA and 100°C for ABS, while prints release easily after cooling. The 0.56mm thick PEI surface withstands light sanding with 600-1000 grit sandpaper to extend its lifespan. Clean between prints with isopropyl alcohol, and install over borosilicate glass for best results.

Best For: Creality Ender 3 and CR 20 owners seeking a durable, high-performance build surface upgrade that provides excellent print adhesion and easy release after cooling.

Pros:

- Made from high-quality Ultem 1000 PEI material with durable 0.56mm thickness that can be refreshed with light sanding

- Features preapplied 3M 468MP adhesive for quick, bubble-free installation without additional prep work

- Provides excellent adhesion during printing while allowing easy print removal once the bed cools down

Cons:

- Limited to specific printer models (Creality Ender 3 and CR 20) with 235mm x 235mm bed size

- Some users report occasional difficulties with print removal requiring tools like spatulas or knives

- May require additional coatings like hair spray for materials that adhere too strongly to the surface

Gizmo Dorks PEI Sheet 3D Printer Build Surface 300mm x 300mm

The Gizmo Dorks PEI Sheet delivers exceptional versatility for makers who work with multiple filament types and demand consistent results across diverse printing projects. This 300mm x 300mm surface accommodates larger printers like the Creality CR-10 and Lulzbot Taz series, featuring genuine Ultem 1000 PEI construction that’s certified to ASTM standards. You’ll appreciate the pre-applied 3M adhesive that simplifies installation—just peel and stick to your glass bed. The surface bonds excellently with PLA, ABS, PETG, and TPU without requiring additional adhesives. When adhesion weakens after extended use, you can restore it by cleaning with isopropyl alcohol or light sanding with 2000-grit sandpaper.

Best For: 3D printing enthusiasts and professionals who use larger format printers and work with multiple filament types, seeking a reliable build surface that eliminates the need for additional adhesives while providing consistent results across diverse printing projects.

Pros:

- Compatible with multiple filament types (PLA, ABS, PETG, TPU) without requiring additional adhesives, tapes, or slurry

- Easy installation with pre-applied 3M 468MP adhesive that simply peels and sticks to glass beds

- Made from certified Ultem 1000 PEI in the USA with ASTM D5205 compliance, ensuring quality and reliability

Cons:

- Large ABS parts may require additional tools for removal, making post-processing more challenging

- Surface adhesion decreases over time and requires regular maintenance with isopropyl alcohol cleaning or sanding

- May need complete replacement after approximately one year of extensive use due to wear

DOBSTFY 3D Printing Build Surface for Ender 3 & CR Series (4 Pack 12x12inch)

Budget-conscious makers will find exceptional value in DOBSTFY’s 3D printing build surface, which delivers PEI-like performance at a fraction of the cost. You’ll get four 12×12-inch sheets that withstand temperatures up to 240°C, making them suitable for both PLA and ABS printing. The thick 1mm construction resists warping while providing excellent adhesion for various filaments including wood and flexible materials. Installation’s straightforward—just peel the 3M backing and stick it down. You can cut sheets to fit different printer sizes, and cleanup with isopropyl alcohol restores effectiveness after multiple prints.

Best For: Budget-conscious 3D printing enthusiasts who want reliable build surface performance across multiple filament types without paying premium PEI prices.

Pros:

- Excellent value with four large 12×12-inch sheets that can be cut to fit various printer sizes

- High temperature resistance up to 240°C with strong adhesion for multiple filament types including PLA, ABS, wood, and flexible materials

- Easy installation with 3M adhesive backing and simple maintenance using isopropyl alcohol

Cons:

- Some users report adhesive residue issues when removing sheets from the print bed

- Instructions could be more comprehensive for optimal setup and usage

- Initial learning curve for proper application and removal techniques

Gizmo Dorks PEI Sheet 3D Printer Build Surface 220mm x 220mm

Advanced 3D printing enthusiasts seeking professional-grade adhesion will find the Gizmo Dorks PEI Sheet an exceptional choice for their build surface needs. This 220mm x 220mm USA-made surface delivers reliable performance across PLA, ABS, and PETG materials with its pre-applied 3M 468MP adhesive backing.

You’ll appreciate the straightforward installation process—simply apply with slight pressure at an angle to prevent air bubbles, then heat your bed to 60°C while applying even pressure. The 0.56mm thick PEI surface provides excellent first-layer adhesion when properly leveled and maintains that grip through countless print cycles. When cleaning’s needed, isopropyl alcohol works perfectly.

Best For: Advanced 3D printing enthusiasts and professionals who need reliable, long-lasting bed adhesion across multiple filament types including PLA, ABS, and PETG.

Pros:

- Pre-applied 3M 468MP adhesive makes installation straightforward with no additional adhesives needed

- Excellent adhesion across multiple filament types (PLA, ABS, PETG) with appropriate temperature settings

- Durable USA-made construction that can be restored with light sanding after extensive use

Cons:

- Requires precise bed leveling and first layer height adjustment for optimal performance

- PETG printing may need careful Z-gap adjustment to prevent over-adhesion issues

- Limited to 220mm x 220mm size which may not fit larger format 3D printers

Kaleidoscope+Skynet Build Plate for 3D Printer (235x235mm Flexible Steel Sheet)

Makers who want both functionality and eye-catching aesthetics will find the Kaleidoscope+Skynet Build Plate an exceptional choice for their 3D printing setup. This 235x235mm flexible steel sheet features dual-sided smooth surfaces with holographic patterns that display different colors under varying lighting conditions.

You’ll appreciate its exceptional flatness that guarantees strong print adhesion across PLA, PETG, ABS, and TPU filaments up to 200°C. The flexible design lets you easily remove prints by bending the sheet after cooling, eliminating the need for scraping tools that can damage surfaces. Users consistently report excellent bed adhesion and long-lasting durability without pattern degradation over time.

Best For: 3D printing enthusiasts who want a durable, aesthetically appealing build plate that provides reliable adhesion across multiple filament types while making print removal effortless.

Pros:

- Dual-sided holographic patterns create visually stunning effects under different lighting conditions while maintaining smooth printing surfaces

- Exceptional flatness and flexibility ensure strong bed adhesion and easy print removal without requiring scraping tools

- Compatible with multiple popular filament types (PLA, PETG, ABS, TPU) and fits various 3D printer models including K1/K1C and Ender series

Cons:

- Some users report that the textured side doesn’t provide optimal first layer aesthetics compared to other build surfaces

- May require Z-offset adjustments during installation due to the build plate’s thickness

- A few users have experienced peeling issues on one side after extended use at higher temperatures

258x258mm Double Sided Flexible PEI Honeycomb Sheet for X1/P1P 3D Printer

The 258x258mm Double Sided Flexible PEI Honeycomb Sheet delivers exceptional versatility for Bambu X1 and P1P printer owners who work with diverse filament types. You’ll appreciate its three-layer construction that withstands temperatures up to 260°C without warping or deformation. This PEI surface handles everything from basic PLA to demanding materials like PC, PA, and TPU with dependable adhesion.

The honeycomb design adds structural integrity while maintaining flexibility for easy print removal. You won’t struggle with stuck prints thanks to its removable nature. Quality inspection guarantees consistent performance, and the manufacturer provides 24-hour customer support for any concerns you might have with this durable build surface.

Best For: 3D printing enthusiasts with Bambu X1/P1P printers who need a versatile build surface that can handle high-temperature materials and provide easy print removal across multiple filament types.

Pros:

- High temperature resistance up to 260°C accommodates demanding materials like PC, PA, and advanced filaments

- Double-sided design with honeycomb structure provides durability while maintaining flexibility for easy print removal

- Compatible with wide range of filaments from PLA to TPU, offering versatility for various printing projects

Cons:

- Does not include soft magnet, requiring separate purchase for magnetic bed attachment

- Temperature adaptation varies by material, requiring manual adjustments and testing for optimal results

- Limited to specific printer sizes (258x258mm), restricting compatibility with other printer models

Creality Ultra-Flexible Removable Magnetic 3D Printer Build Surface (310X310MM)

For FDM printer owners seeking hassle-free print removal without tools, Creality’s Ultra-Flexible Removable Magnetic Build Surface delivers exceptional convenience through its two-part magnetic system. You’ll stick Part B’s adhesive base to your build plate, then place Part A’s matte surface on top. After printing, simply flex the upper sheet and your models pop off effortlessly.

This 310x310mm surface works perfectly with PLA filaments on heated and non-heated beds. You won’t need spatulas or knives anymore. The customizable surface cuts to fit various printer sizes, and users report minimal wear over time. However, you’re limited to temperatures below 70°C, making it unsuitable for high-temperature materials like ABS or PETG.

Best For: FDM printer owners who primarily print with PLA filaments and want effortless print removal without using tools like spatulas or knives.

Pros:

- Effortless print removal through flexible magnetic surface that allows models to pop off easily after cooling

- Universal compatibility with all FDM printers and both heated/non-heated beds, plus customizable sizing

- Durable construction with minimal wear over time compared to other build surface materials

Cons:

- Limited to low-temperature applications (below 70°C), making it unsuitable for ABS, PETG, and other high-temp filaments

- Requires proper bed leveling and maintenance to ensure adequate print adhesion

- Two-part installation process that must be applied carefully to avoid air bubbles

G10 Fiberglass Garolite 3D Printer Build Surface Plate (235mm Black)

Professional 3D printing enthusiasts and makers working with challenging materials will find the G10 Fiberglass Garolite build surface plate an exceptional upgrade from standard printing surfaces. This 2mm thick composite material handles high temperatures up to 266℉ while providing excellent adhesion for sticky filaments like Nylon, PETG, ABS, and even engineering plastics like PEEK and ULTEM. You’ll appreciate how prints self-release when cooling, eliminating the need for aggressive removal techniques that damage surfaces. The fiberglass construction resists scratches, moisture, and impacts better than glass alternatives. Simply clip it onto your heated bed and clean with isopropyl alcohol for reliable, long-term performance.

Best For: Professional 3D printing enthusiasts and makers who work with challenging materials like Nylon, PETG, ABS, and engineering plastics requiring reliable adhesion and high-temperature resistance.

Pros:

- Excellent adhesion for sticky filaments without bed preparation, with prints self-releasing upon cooling

- High temperature resistance up to 266℉/130℃ and superior durability against scratches, moisture, and impacts

- Easy installation by clipping onto heated bed with simple isopropyl alcohol cleaning for maintenance

Cons:

- Requires a heated bed for optimal performance, limiting compatibility with basic 3D printers

- Some users report receiving scratched or defective plates with inconsistent surface quality

- May require wet sanding with 2000 grit to enhance adhesion for certain materials

Factors to Consider When Choosing the Most Durable Build Surface Materials for 3D Printers

When you’re selecting a durable build surface for your 3D printer, you’ll need to evaluate several critical factors that directly impact your printing success and long-term costs. The material’s temperature resistance, adhesion properties, and compatibility with different filaments will determine how well it performs across various projects. You should also consider the surface’s expected lifespan, wear patterns, and maintenance requirements to guarantee you’re making a cost-effective investment.

Material Temperature Resistance

Since your 3D printer’s build surface must withstand prolonged exposure to high temperatures, you’ll need to evaluate each material’s temperature resistance before making a selection. Many quality build surfaces can handle temperatures up to 260°C without deformation, ensuring structural integrity during demanding prints.

When you’re printing ABS or PETG, which require heated beds at 100°C and 75°C respectively, temperature resistance becomes critical. G10 fiberglass Garolite excels here, withstanding up to 130°C while providing excellent adhesion without additional preparation. PEI sheets handle 60°C to 100°C, making them versatile for various thermoplastics.

You must match your build surface’s maximum temperature rating with your filament requirements. Exceeding these limits causes warping, poor adhesion, and permanent damage to your build plate.

Adhesion and Release

Two essential performance factors determine your build surface’s effectiveness: how well it grips prints during fabrication and how easily it releases them afterward. You’ll need strong adhesion to prevent warping and guarantee model stability, especially with PLA, ABS, and PETG filaments. However, you also want prints to self-release upon cooling, reducing damage risks to both your model and surface.

Temperature settings play an important role in this balance. PLA typically adheres well at 55°C, while ABS requires up to 100°C for ideal bonding. Some surfaces exhibit excessive adhesion with flexible filaments, requiring release agents or surface adjustments.

Regular maintenance extends your surface’s effectiveness. Clean with isopropyl alcohol or wet sand periodically to maintain proper adhesion and release characteristics.

Longevity and Wear

Although adhesion and release properties determine your build surface’s immediate performance, longevity factors ultimately decide whether you’ll replace it in months or years.

Temperature resistance stands as your primary concern—you’ll need materials that withstand temperatures exceeding 260°C without warping or degrading. G10 fiberglass and Ultem PEI excel here, offering superior resistance to moisture, chemicals, and physical impacts that extend service life considerably.

Thickness matters more than you’d expect. Thicker surfaces provide better rigidity and resist heat-induced warping that destroys thinner alternatives.

Your maintenance routine directly impacts longevity. Regular cleaning with isopropyl alcohol and occasional light sanding dramatically extends performance life.

Consider your printing habits too—high-frequency users and those printing abrasive filaments will experience faster wear regardless of material choice.

Filament Compatibility Range

Your filament selection determines which build surfaces will deliver consistent, reliable performance across different printing projects. PEI sheets excel with thermoplastics like PLA and ABS, providing excellent adhesion without additional adhesives across a wide temperature range. For sticky materials such as Nylon, PETG, and TPU, G10/FR4 surfaces offer superior compatibility with high-temperature resistance that won’t degrade over time.

Flexible steel sheets deliver versatility by supporting PLA, PETG, and TPU effectively, making them ideal if you frequently switch between materials. Consider your typical bed temperatures too—PLA works well around 55°C, while ABS demands up to 100°C. Choose surfaces that handle your specific filament requirements and operating temperatures to guarantee long-term durability and consistent first-layer adhesion.

Maintenance Requirements

Three key maintenance factors directly impact your build surface’s lifespan and printing consistency. First, you’ll need regular cleaning with isopropyl alcohol or soap and water to maintain peak adhesion and prevent residue buildup. Second, surface restoration becomes necessary over time—PEI sheets require light sanding with fine grit sandpaper after extensive use, while G10 Garolite needs wet sanding to enhance adhesion, especially for ABS printing. Third, following manufacturer temperature settings and maintenance guidelines guarantees consistent print quality and prolongs surface life. Remember that different materials wear at varying rates depending on your printing frequency and filament types, so you’ll eventually need replacements regardless of maintenance quality.

Installation and Setup

Proper installation determines whether your chosen build surface will deliver its expected durability and performance benefits. Start by cleaning your existing print bed thoroughly with isopropyl alcohol to guarantee ideal adhesion and prevent air bubbles. Choose pre-applied adhesive options for easier installation, applying the surface with slight pressure at an angle to minimize trapped air.

For PEI sheets, you’ll need to heat your print bed to the manufacturer’s specified temperature after application to secure the adhesive bond effectively. Some surfaces require additional tools like clips or weighted pressure to maintain flatness during printing. Remember that proper installation directly impacts your surface’s longevity—rushed or improper application can lead to premature failure and reduced printing quality.

Frequently Asked Questions

How Often Should I Replace My 3D Printer Build Surface?

You should replace your build surface when it’s damaged, warped, or prints won’t stick properly. Glass and PEI sheets typically last months, while tape and adhesive surfaces need replacement every few prints.

Can I Use the Same Build Surface for Different Filament Types?

You can use the same build surface for different filament types, but you’ll need to adjust bed temperatures and may experience varying adhesion levels depending on each material’s specific requirements.

What’s the Best Way to Clean Build Surfaces Without Damaging Them?

You’ll want to use isopropyl alcohol with a microfiber cloth for most surfaces. Don’t use acetone on PEI or textured beds. Let surfaces cool completely before cleaning to prevent warping or cracking damage.

Do Thicker Build Surfaces Provide Better Durability Than Thin Ones?

You’ll find thicker build surfaces generally offer better durability since they resist warping, handle more abuse, and last through countless print removals. However, they’re costlier and may affect heat transfer slightly.

How Do I Know When My Build Surface Needs Replacement?

You’ll notice your build surface needs replacement when prints won’t stick properly, you see visible scratches or gouges, the surface feels rough, or cleaning doesn’t restore adhesion anymore.

Leave a Reply