You’re probably tired of dealing with wobbly prints and inconsistent layer quality from your 3D printer’s stock motion system. Linear rail conversion kits can transform your machine’s performance, delivering the precision and smooth motion you’ve been craving. However, not all kits are created equal, and choosing the wrong one could leave you frustrated with installation headaches and minimal improvements. Three standout options have emerged from extensive testing, each offering distinct advantages depending on your specific needs.

Creativity Upgrade Y Axis Linear Rail Guide Kit MGN12H for Ender3 3D Printer

The Creativity Upgrade Y Axis Linear Rail Guide Kit MGN12H stands out with its dual rail design that delivers superior stability compared to single rail alternatives. You’ll find compatibility with Ender-3, Ender-3 Pro, and Ender-3 V2 models, though you’ll need to print an additional Y-axis limit block for V2 assembly.

While many users report improved print quality and smoother operation, you should be aware of potential quality control issues. Some rails arrive bent, causing binding problems, and bearings may feel rough despite lubrication. You’ll also encounter design limitations like build plate interference and occasionally missing ball bearings that create clicking sounds during operation.

Best For: DIY 3D printer enthusiasts with technical experience who want to upgrade their Ender-3 series printer’s stability and are comfortable with potential troubleshooting and quality control issues.

Pros:

- Dual rail design provides superior stability and smoother operation compared to single rail systems

- Compatible with multiple Ender-3 models (Ender-3, Pro, and V2) with quick installation process

- Users report improved print quality and enhanced overall printing performance

Cons:

- Quality control issues including bent rails, rough bearings, and missing ball bearings in some units

- Design limitations such as build plate interference with belt tensioner and Y-end stop compatibility issues with Ender-3 V2

- Lacks clear installation instructions and may require custom printed parts for proper assembly

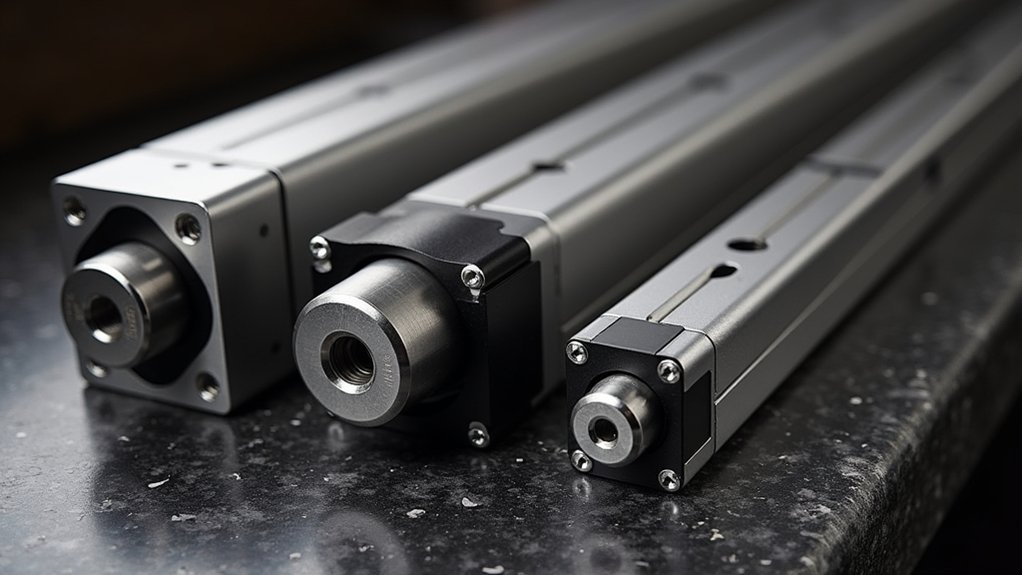

3D Printer CNC Linear Rail MGN12H 400mm (2pcs Blocks)

Precision enthusiasts and CNC builders will find exceptional value in the 3D Printer CNC Linear Rail MGN12H 400mm kit, which delivers industrial-grade performance through its 78-bead slider system and self-aligning capabilities. You’ll appreciate the full body polishing that guarantees smooth movement without resistance, while the low friction coefficient bearing steel construction provides stronger wear resistance. The kit’s high module accuracy and special bead retention design prevent component loss during operation. You can rely on the versatile compatibility with various installation surfaces, making it suitable for semiconductor manufacturing, robotic arms, and precision measurement machines.

Best For: Precision enthusiasts, CNC builders, and professionals working on 3D printers, robotic arms, semiconductor manufacturing, or precision measurement equipment who need reliable linear motion systems with high load capacity and smooth operation.

Pros:

- 78-bead slider system provides exceptional load capacity and smooth, steady movement with self-aligning capabilities

- Full body polished rail with low friction coefficient bearing steel ensures minimal resistance and enhanced wear resistance

- High compatibility with various installation surfaces and comes pre-oiled with 1-year warranty and 24-hour support

Cons:

- Some users reported dimensional discrepancies in rail length and flatness affecting machining quality

- Product listing clarity issues with some customers expecting rails to be included with blocks

- May require additional lubrication after cleaning and potential modifications like ball bearing replacement for optimal performance

Creality Ender 3 Linear Rail Kit X-axis Rail Guide (MGN12C)

Official Creality support makes this linear rail kit an ideal choice for Ender 3 owners seeking a reliable upgrade path with manufacturer backing. You’ll get compatibility across Ender 3, Pro, and V2 models, plus mounting brackets for Sprite Pro extruders. The high carbon chromium steel construction reduces vibrations while enabling faster printing speeds with lower energy consumption.

Installation takes under an hour for experienced users, though you’ll need clearer instructions. Don’t forget to remove blue shipping stops before operation. While some users received damaged units, Creality’s responsive customer service quickly provides replacements, making this kit worthwhile despite occasional quality control issues.

Best For: Ender 3 owners with experience modifying their printers who want an official manufacturer upgrade to improve print precision and speed with reliable customer support backing.

Pros:

- High carbon chromium steel construction reduces vibrations and enables faster printing speeds with lower energy consumption

- Official Creality support ensures compatibility across Ender 3, Pro, and V2 models with included Sprite Pro extruder mounting brackets

- Quick installation under one hour for experienced users with responsive customer service providing fast replacements if needed

Cons:

- Installation instructions are unclear and may require prior experience with Ender printer modifications

- Quality control issues with some users receiving damaged rails, though replacements are provided

- Some users suggest sourcing individual components for better specifications like MGN12H rails or longer lengths to avoid print volume loss

Factors to Consider When Choosing Linear Rail Conversion Kits

When you’re selecting a linear rail conversion kit, you’ll need to evaluate several critical factors that directly impact your upgrade’s success. The rail type and size must match your printer’s specifications, while ensuring complete compatibility with your specific printer model. You should also assess the installation complexity, verify the manufacturer’s quality control standards, and confirm the kit includes all necessary components for a complete conversion.

Rail Type and Size

Although linear rail conversion kits might look similar at first glance, the rail type and size you choose will make or break your upgrade’s success. You’ll encounter different rail types like MGN12H or MGN12C, each offering distinct performance characteristics. MGN12H features 78 beads in its blocks, delivering superior load capacity and reduced wear compared to other variants.

Rail size matters equally. You’ll need to match length and height specifications—whether 300mm or 400mm—to your specific 3D printer model. The combined height and threading specifications must align with your existing mounting hardware for secure attachment to the printer frame. Don’t overlook the single versus dual rail decision either. Dual rail systems provide enhanced stability and better print quality by offering more support and reducing operational binding.

Printer Model Compatibility

Three critical compatibility factors determine whether your linear rail conversion kit will integrate seamlessly with your 3D printer. First, you’ll need a kit specifically designed for your exact printer model, as compatibility varies considerably between different 3D printer types. Second, verify the rail dimensions match your printer’s X-axis or Y-axis requirements perfectly. Third, look for kits that explicitly state compatibility with multiple versions of your printer model—like Ender-3, Ender-3 Pro, and Ender-3 V2—to avoid installation headaches.

Before purchasing, check if you’ll need additional components or custom printed parts for proper functionality. Read user reviews focusing on installation experiences and performance improvements for your specific model to understand real-world compatibility and effectiveness.

Installation Complexity Level

Installation complexity represents another key factor that’ll greatly impact your conversion experience and time investment. While straightforward kits can be installed in under an hour by experienced builders, unclear instructions and missing components will extend your project timeline considerably. You’ll often encounter alignment challenges that require careful adjustments to guarantee proper rail function. Some kits demand additional parts like custom limit blocks or require swapping existing components such as hotend covers for compatibility. The quality of provided instructions directly affects installation ease, and you may need specialized tools beyond basic hex keys. Consider your technical skill level and available time when selecting a kit, as complexity varies dramatically between manufacturers and printer models.

Quality Control Standards

Quality control standards determine whether your linear rail conversion will deliver the precision and reliability you’re expecting from your upgrade investment. You’ll want manufacturers who rigorously test rail straightness and flatness to prevent binding issues that compromise smooth operation. Look for rails with full body polishing, which enhances surface smoothness and reduces friction during movement.

Check that blocks contain sufficient ball bearings to support proper load capacity and eliminate clicking sounds during operation. Verify that installation components like bolts and sliders meet standardized specifications for compatibility and easy assembly.

Don’t overlook warranty and customer support policies. Quality manufacturers offer clear policies with prompt assistance and replacement options when quality control issues arise, protecting your investment long-term.

Complete Kit Contents

Thorough examination of what’s actually included in your linear rail conversion kit prevents costly surprises and project delays. You’ll need to verify the complete packing list contains rails, blocks, mounting hardware, and any necessary limit switches or printed components. Some kits require additional printed parts like Y-axis limit blocks for specific printer models, so plan accordingly.

Pay attention to hardware quantities and specifications, as bolt and nut counts vary greatly between manufacturers. This directly impacts installation ease. Check for specific assembly requirements or alignment adjustments your printer model might need.

Don’t overlook bearing quality and quantity—blocks with 78 high-quality beads versus fewer components will profoundly affect your system’s performance and longevity. Verify everything’s included before starting installation.

Performance Enhancement Goals

Understanding your performance targets helps determine which linear rail specifications will deliver the improvements you’re seeking. If you’re aiming for enhanced stability and smoother operation, upgrading to dual linear rails like MGN12H will greatly improve your print quality. When targeting reduced vibrations and increased precision, prioritize high-quality rail materials such as high carbon chromium steel. For higher print speeds, consider rails with more beads in the blocks—MGN12H’s 78 beads improve load capacity and support smoother movement. Remember that achieving these performance goals requires proper alignment and installation, as misalignment causes binding issues that’ll negatively impact print quality. Regular maintenance through lubrication and wear checks guarantees you’ll maintain ideal performance and extend your linear rail system’s longevity.

Frequently Asked Questions

How Long Does Installation Typically Take for a Linear Rail Conversion Kit?

You’ll typically spend 2-4 hours installing a linear rail conversion kit, depending on your experience level and printer complexity. If you’re familiar with 3D printer mechanics, you’ll finish faster than beginners.

Can Linear Rail Kits Be Used on Other 3D Printer Brands?

You can use linear rail kits on most 3D printer brands, but you’ll need to verify mounting compatibility and dimensions. Many kits work with popular brands like Ender, Prusa, and Voron with proper adaptation.

What Maintenance Is Required After Installing Linear Rail Conversion Kits?

You’ll need to regularly clean the rails with isopropyl alcohol, lubricate the bearings monthly, check for loose bolts, and inspect for wear. Don’t over-lubricate as it attracts debris and reduces performance.

Do Linear Rails Significantly Reduce Printing Noise Compared to Stock Systems?

You’ll notice considerably quieter operation with linear rails since they eliminate the grinding and vibration of roller wheels on aluminum extrusions, creating smoother motion that reduces mechanical noise during printing.

Are There Warranties Available for Linear Rail Conversion Kit Components?

You’ll find most reputable manufacturers offer limited warranties on linear rail components, typically covering defects for 6-12 months. However, warranty terms vary considerably between brands, so you should always verify coverage before purchasing conversion kits.

Leave a Reply