You’ve probably experienced that sinking feeling when your first layer fails, ruining hours of potential print time. The build plate you choose makes all the difference between consistent success and frustrating failures. While many factors affect print quality, your build surface determines whether filament adheres properly or warps into an unusable mess. Three specific plate types consistently outperform others, but selecting the wrong one for your filament type will guarantee disappointing results.

3D Printer Glue Stick (3 Pack) for ABS PLA PETG Filaments

If you’re struggling with prints that warp, lift, or fail to stick properly to your build plate, the TEQStone JT16 3D printer glue stick offers a reliable solution that works across multiple filament types and surface materials. This 3-pack provides strong adhesion for ABS, PLA, PETG, and even difficult materials like polypropylene on textured PEI, glass, aluminum, and flexible surfaces.

You’ll appreciate the water-soluble formula that applies cleanly like a Pritt stick without mess. Each 36g stick delivers over 100 prints, making the 3-pack cost-effective for 300+ prints. The pleasant lemon scent and easy cleanup with damp cloth add convenience. Just apply carefully—some users find it surprisingly strong for certain projects.

Best For: 3D printing enthusiasts who struggle with warping, lifting, or poor bed adhesion across multiple filament types (ABS, PLA, PETG) and various build surface materials.

Pros:

- Strong adhesion that prevents warping and lifting while still allowing easy print removal thanks to water-soluble formula

- Works effectively across multiple filament types and surface materials including textured PEI, glass, aluminum, and flexible surfaces

- Excellent value with each stick lasting 100+ prints and mess-free application similar to a Pritt stick

Cons:

- May provide overly strong adhesion for certain projects requiring more careful application

- Limited to water-soluble cleanup method which may not suit all workshop preferences

- Takes some experimentation to find optimal application amount for different materials and projects

3D Printer Build Plate Adhesive and Cleaner

Ready 3D adhesive transforms your 3D printing experience by delivering first-layer perfection across multiple filament types, making it the ideal choice for makers who demand reliable bed adhesion without the hassle of brims or warping issues. You’ll appreciate the easy sponge applicator that dispenses glue evenly, drying clear without any flaky residue. One application lasts through multiple prints, saving you time and effort. The included cleaner removes previous print residue and oils without damaging your build plate surface, while the provided cleaning cloth adds convenience to your maintenance routine, keeping your printing surface pristine for consistent results.

Best For: 3D printing enthusiasts and professionals who need reliable bed adhesion across multiple filament types (PLA, ABS, PETG, ASA, TPU) and want to eliminate warping issues while reducing post-print processing time.

Pros:

- Easy sponge applicator provides even distribution and dries clear without flaky residue, with one application lasting multiple prints

- Works effectively across various filament types and allows printing without brims, improving print quality and reducing post-processing

- Includes specifically formulated non-toxic cleaner and cleaning cloth for complete maintenance solution

Cons:

- Some users experienced product leakage during shipping, resulting in product loss

- Mixed reviews on adhesion performance with reports of poor adhesion on specific build plate surfaces

- Limited information provided about compatibility with all build plate materials and surface types

150ml 3D Printer Adhesive Glue for PLA, PETG, ASA, TPU Filaments

This 150ml 3D printer adhesive glue delivers exceptional first-layer adhesion for makers who demand reliable prints across multiple filament types. You’ll get strong adhesion for PLA, PETG, ASA, TPU, ABS, and HIPS filaments on glass, PEI sheets, aluminum, and Buildtak surfaces. The formula reduces warping and shifting while providing over 120 coatings that support 3-10 prints each – that’s at least 1200 total prints. You’ll appreciate the easy dabber application and water-soluble cleanup. The odorless formula won’t create unpleasant fumes when heated, making it perfect for articulated prints and complex designs.

Best For: Makers who frequently 3D print with multiple filament types and need reliable first-layer adhesion across various build surfaces.

Pros:

- Compatible with 6 different filament types (PLA, PETG, ASA, TPU, ABS, HIPS) and multiple build surfaces

- Excellent value with 150ml providing over 120 coatings for at least 1200 total prints

- Water-soluble formula with easy cleanup and odorless operation when heated

Cons:

- Can be difficult to remove prints if too much glue is applied

- Some users report challenges with excess glue causing print damage

- May require experimentation with solvents like acetone for thorough residue removal

Factors to Consider When Choosing 3D Printer Build Plates for Perfect First Layers

When you’re selecting a build plate for your 3D printer, you’ll need to assess several critical factors that directly impact your first layer quality and overall print success. The surface material you choose must provide proper adhesion for your specific filaments while withstanding the temperature requirements of your printing process. You’ll also want to contemplate how easy the plate is to clean and maintain, as these factors affect both print quality and the longevity of your investment.

Surface Material Types

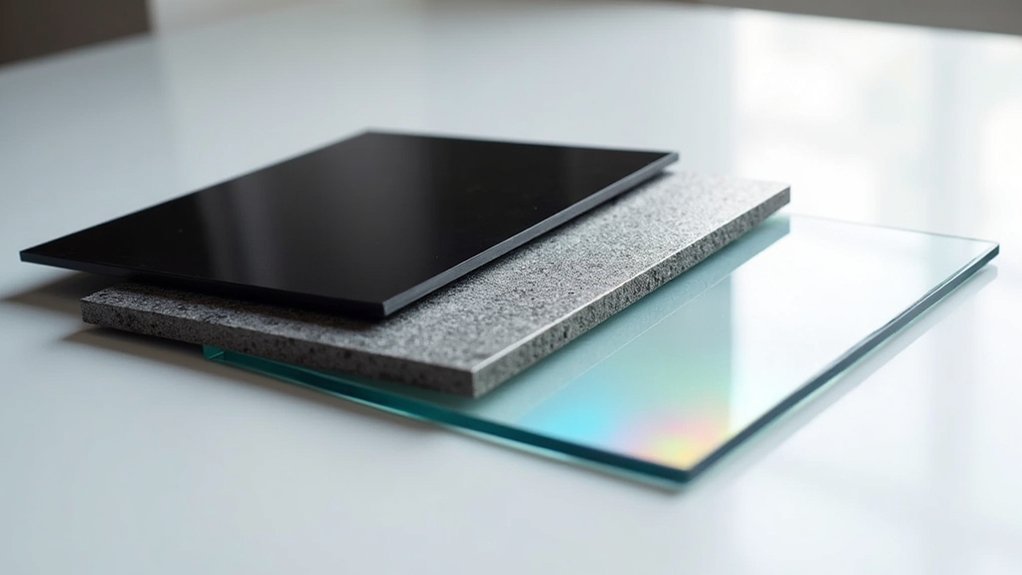

Success in 3D printing starts with selecting the right build plate surface material for your specific filament and project requirements. Glass surfaces deliver smooth finishes and easy cleaning, making them perfect for PLA and PETG while ensuring even heat distribution. You’ll find aluminum plates offer excellent durability and heat retention, preventing warping issues with ABS and ASA materials. PEI sheets provide outstanding adhesion across multiple filament types, creating strong holds during printing yet allowing effortless removal when cooled. Buildtak surfaces give you aggressive grip strength during printing but require diligent cleaning maintenance, especially when working with high-temperature filaments. Each material type offers distinct advantages depending on your printing needs.

Adhesion Enhancement Methods

While your build plate surface provides the foundation, adhesion enhancement methods give you the extra grip needed to secure challenging prints and prevent first-layer failures. Water-soluble adhesive solutions offer the perfect balance of strong hold and easy cleanup. You’ll get strong adhesion that prevents warping and shifting, especially when printing challenging materials like ABS and TPU. These solutions typically provide over 120 coatings per application, giving you multiple successful prints before reapplication.

Use a dabber or sponge applicator for clean, even coverage that minimizes mess and maximizes performance. When prints complete, simply clean up with a damp cloth or water rinse. Don’t hesitate to experiment with different adhesives—you’ll often find improved print stability for intricate designs and larger models.

Temperature Resistance Requirements

Temperature resistance forms the backbone of reliable 3D printing, as your build plate must handle the thermal demands of various filaments without compromising performance. You’ll need a plate that reaches 60-70°C for PLA, 100-110°C for ABS, and 70-80°C for PETG while maintaining structural integrity. Your build plate mustn’t warp or degrade under sustained high temperatures, especially when printing advanced materials that require extended heating cycles.

Consistent temperature distribution across the entire surface prevents adhesion failures that cause layer shifting in large prints. You’ll want a build plate with excellent thermal conductivity to guarantee rapid, even heat distribution. This uniform heating creates stable first layers and prevents thermal fluctuations that compromise print quality. Choose materials that won’t crack or lose flatness when repeatedly cycled through temperature extremes.

Cleaning and Maintenance

Three key cleaning considerations will determine your build plate’s long-term performance and print success. First, you’ll need to remove residue from previous prints and oils regularly to guarantee ideal adhesion for new first layers. Choose water-soluble adhesives when possible—they’ll simplify your cleanup routine since you can wipe the surface with a damp cloth or rinse with water without damage.

Second, use appropriate cleaning agents to prevent residue buildup. Some adhesives leave stubborn remnants that require dedicated cleaning solutions. These specialized products remove adhesive residues without harming your build plate material.

Third, establish a maintenance routine that includes periodic cleaning and damage inspection. Proper upkeep enhances adhesion performance, prolongs your build plate’s lifespan, and reduces warping or shifting during prints.

Filament Compatibility Considerations

Before selecting any build plate, you must match it to your specific filament types since each material demands different adhesion properties for successful first layers. ABS requires heated surfaces to prevent warping, while PLA adheres well to various surfaces without heat. Consider your build plate’s material carefully—glass, PEI, and aluminum each offer different adhesion levels that’ll impact your printing success.

Textured surfaces enhance adhesion for challenging prints, especially larger models or complex geometries prone to shifting during printing. If you’re working with difficult materials like polypropylene, you’ll need specialized adhesives or glues to achieve proper stability. Match your surface choice to your most frequently used filaments, ensuring compatibility across your entire material library for consistent results.

Cost and Longevity

Build plate costs range from budget-friendly options under $20 to premium surfaces exceeding $100, but you’ll find that higher upfront investments typically deliver superior long-term value. Quality build plates can handle over 1200 prints per coating, making them remarkably cost-effective compared to frequent replacements of cheaper alternatives.

You should evaluate adhesive solutions carefully, as some can be reused across multiple prints, greatly reducing your ongoing material expenses. While budget plates might seem attractive initially, they often require more frequent replacements and maintenance, increasing your total ownership costs.

Proper maintenance and careful adhesive application will extend your build plate’s lifespan considerably. When you factor in reduced downtime, consistent performance, and fewer failed prints, investing in a durable build plate becomes a smart financial decision.

Frequently Asked Questions

How Often Should I Replace My 3D Printer Build Plate?

You should replace your build plate when it shows visible wear, scratches, or warping that affects print adhesion. Glass plates last longer than flexible ones. Typically, you’ll need replacement every 6-12 months with regular use.

Can I Use the Same Build Plate for Different Printer Models?

You can’t universally swap build plates between different printer models. Each printer’s got specific mounting systems, bed sizes, and heating requirements. Check your printer’s compatibility specifications before transferring plates to avoid damage or poor performance.

What’s the Difference Between Heated and Non-Heated Build Plates?

Heated plates warm up to prevent warping and improve adhesion, especially with materials like ABS. Non-heated plates work fine for PLA but you’ll struggle with higher-temperature filaments that shrink when cooling.

How Do I Know if My Build Plate Is Properly Leveled?

You’ll know your build plate’s properly leveled when your first layer shows consistent extrusion width across the entire surface. If you’re seeing gaps, uneven lines, or poor adhesion in corners, you’ll need to readjust your leveling.

Are Glass Build Plates Better Than Metal Ones for Beginners?

Glass plates offer better flatness and easier print removal, but you’ll need more precise leveling skills. Metal plates heat faster and forgive minor leveling errors, making them more beginner-friendly for your first attempts.

Leave a Reply