You’re witnessing edible metals like gold and silver transform food printing by creating luxurious, Instagram-worthy dishes that command premium prices. These FDA-approved metals integrate seamlessly into 3D printing inks, offering antimicrobial properties that extend shelf life while delivering stunning visual appeal. They’re revolutionizing restaurants and commercial food manufacturing by enabling personalized, high-end presentations that differentiate products in competitive markets. The technology combines cutting-edge extrusion-based printing with food-grade metallic formulations, driving the industry toward a projected $20 billion market transformation by 2025.

The Science Behind Edible Metal Integration in Food Printing

When you incorporate edible metals like gold and silver into food printing, you’re working with specially processed materials that undergo rigorous refinement to achieve food-grade safety standards.

These metals are transformed into ultra-thin sheets or flakes that seamlessly integrate into various food structures without compromising taste or texture. You’ll find that regulatory approvals support their safe consumption in appropriate quantities.

The science reveals these edible metals offer antimicrobial properties that naturally extend your printed food’s shelf life.

During the printing process, innovations in metal formulations improve adhesion to food surfaces, enhancing overall printing capabilities.

You’re fundamentally utilizing materials that serve dual purposes: creating visually stunning culinary designs while providing functional preservation benefits that traditional food ingredients can’t match.

Safety Standards and Regulatory Compliance for Edible Metals

Beyond the technical innovations that make edible metal integration possible, you must navigate a complex landscape of safety standards and regulatory requirements before these materials reach your kitchen.

The FDA classifies edible metals like gold and silver leaf as food additives, demanding strict adherence to Good Manufacturing Practices. You’ll find these safety regulations guarantee manufacturers maintain quality throughout production while protecting food safety.

Regulatory compliance extends beyond manufacturing—you’ll see clear labeling requirements that identify edible metals on ingredient lists. Health authorities establish specific quantity limits to prevent toxicity, and they conduct regular inspections to verify standards are met.

This extensive regulatory framework maintains consumer trust while guaranteeing edible metals revolutionize food printing safely and responsibly.

Enhanced Aesthetic Appeal Through Metallic Food Elements

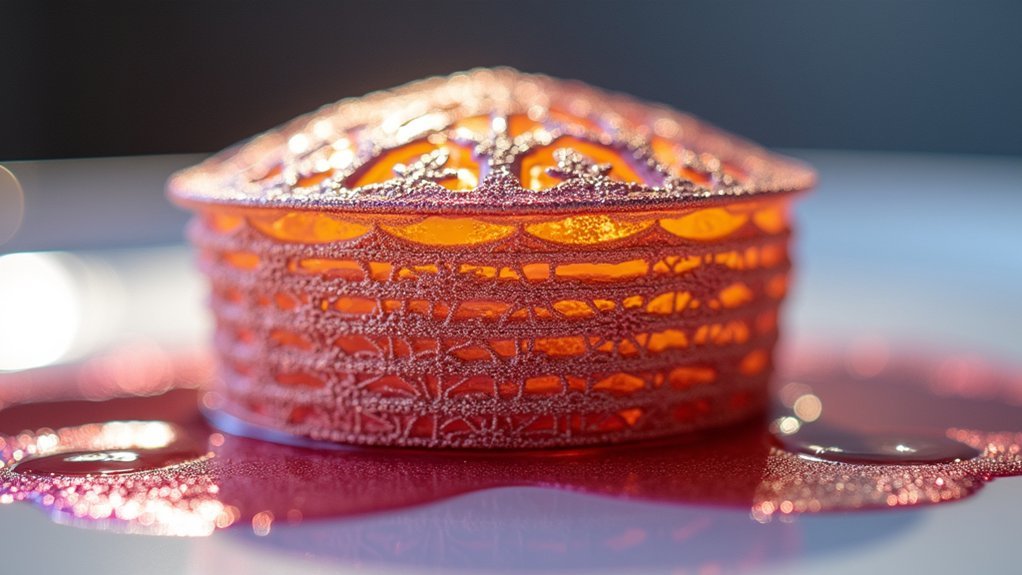

Culinary artistry reaches new heights when you incorporate edible metals into food printing applications.

You’re transforming ordinary dishes into extraordinary visual masterpieces that captivate customers and justify premium pricing. Modern printing techniques enable precise placement of gold and silver leaf, creating stunning reflective surfaces that photograph beautifully for social media.

Modern culinary printing transforms humble ingredients into dazzling metallic masterpieces that command premium prices and social media attention.

Your metallic food elements deliver three key advantages:

- Luxury positioning – Edible metals instantly elevate perceived value and sophistication

- Market differentiation – Stand out from competitors with eye-catching presentations

- Customer engagement – Generate Instagram-worthy moments that drive organic marketing

You’ll find edible metals particularly effective in high-end desserts and gourmet dishes where visual appeal directly impacts sales.

These unique experiences satisfy consumers’ growing demand for memorable dining moments while boosting your profit margins through enhanced perceived value.

Nutritional Benefits and Health Properties of Edible Metals

Emerging research reveals that edible metals offer more than visual enhancement in food printing applications. You’ll find that gold and silver bring potential nutritional benefits beyond their striking appearance.

Gold’s anti-inflammatory properties may support your digestive health, though researchers need more studies to confirm these effects. These health properties are increasingly influencing consumer purchasing behavior as you seek unique dining experiences that combine luxury with wellness.

When you choose foods containing edible metals, you’re accessing products that regulatory authorities recognize as safe in small quantities. The perceived health benefits of these metals align with your growing demand for innovative food experiences.

You’re fundamentally investing in products that promise both aesthetic appeal and potential wellness advantages, making edible metals a compelling addition to modern food printing technology.

3D Printing Technologies Compatible With Edible Metal Inks

When you’re working with edible metal inks, you’ll find that extrusion-based printers offer the most reliable compatibility for precise application and smooth material flow.

You’ll need to address layer adhesion challenges that arise when metallic particles don’t bond properly with food substrates, potentially causing print failures or uneven finishes.

You must also maintain strict temperature control throughout the printing process, as heat fluctuations can alter the ink’s viscosity and compromise both print quality and food safety standards.

Extrusion-Based Printer Compatibility

Although traditional 3D printers weren’t designed for culinary applications, extrusion-based systems have proven remarkably adaptable to edible metal inks through strategic modifications.

You’ll find that extrusion-based printers can accommodate these specialized materials by incorporating particular components that handle metallic formulations’ unique viscosity and particulate characteristics.

When working with these printing processes, you’ll need to take into account three essential elements:

- Specialized nozzles designed for metallic ink flow patterns

- Heated cartridges that maintain consistent temperature controls

- Enhanced pressure systems that guarantee smooth material dispensing

This compatibility allows manufacturers to create innovative applications ranging from metallic confectionery coatings to nutrient-rich edible structures.

You’ll discover that manufacturers are increasingly optimizing their machines specifically for edible metal inks, expanding possibilities in culinary innovation sectors.

Layer Adhesion Challenges

Layer adhesion presents vital obstacles that you’ll encounter when working with edible metal inks in 3D food printing applications. Poor bonding between layers directly compromises your printed food’s structural integrity, leading to delamination and product failure.

You’ll need to optimize ink viscosity carefully—ensuring proper flow through nozzles while maintaining sufficient adhesion during the printing process.

To overcome these challenges, you can pre-heat substrates or incorporate specific binding agents that strengthen layer bonds. Understanding rheological properties becomes essential, as edible metal inks behave differently under shear stress compared to conventional materials.

Your choice of printing technology also matters greatly. Binder jetting and material extrusion exhibit varying compatibility levels with edible metal inks, affecting your ability to achieve reliable layer adhesion in multi-layered food structures.

Temperature Control Requirements

Beyond addressing adhesion issues, you must master temperature control requirements to successfully print with edible metal inks. Your 3D food printers need precise thermal management throughout the printing process to maintain ideal viscosity and prevent material degradation.

Temperature control becomes critical when working with edible metals because variations affect crystallization patterns, directly impacting your final product’s texture and appearance.

Here’s what you’ll need:

- Heated print heads that maintain consistent temperatures between 30°C to 60°C for proper melting and extrusion

- Advanced monitoring systems that prevent temperature fluctuations and reduce clogging risks

- Precise thermal regulation that guarantees accurate layering and detail preservation in your designs

Without proper temperature management, you’ll face inconsistent results and compromised print quality in your edible metal applications.

Market Applications Across Culinary and Food Manufacturing Industries

You’ll find edible metal printing transforming luxury restaurants where chefs create stunning, personalized dishes that command premium prices.

Commercial food manufacturers are adopting this technology to mass-produce visually striking confections and desserts that stand out on retail shelves.

You can also leverage edible metal inks for custom packaging solutions that print directly onto food surfaces, eliminating traditional wrapper needs while enhancing brand differentiation.

Luxury Restaurant Applications

As luxury restaurants compete for discerning clientele, they’re increasingly incorporating edible metals like gold and silver leaf into their culinary presentations to create an immediate sense of opulence and exclusivity.

You’ll find these establishments using food printing technology to precisely apply metallic elements that transform ordinary dishes into extraordinary experiences.

When you visit these high-end venues, you’re likely to encounter:

- Cocktails adorned with shimmering gold leaf that dissolve elegantly as you sip

- Desserts featuring intricate silver patterns printed directly onto pastries and plated presentations

- Signature dishes with metallic accents that serve as Instagram-worthy centerpieces

These luxury restaurant applications leverage edible metals to differentiate their offerings while creating unique dining experiences that justify premium pricing and encourage social media engagement among your guests.

Commercial Food Production

Three major sectors drive the commercial adoption of edible metals in food production: confectionery manufacturing, artisanal bakeries, and specialty beverage companies.

You’ll find that commercial food production increasingly relies on edible materials like gold and silver leaf to create premium product lines. The food printing industry benefits from these metals’ ability to enhance visual appeal while maintaining safety standards through FDA compliance.

You’re witnessing a $20 billion market transformation by 2025, where manufacturers use printing techniques with edible materials to differentiate their offerings.

Commercial food production facilities integrate these metals into chocolates, pastries, and beverages, creating unique selling propositions that command premium pricing. This trend allows you to access luxury food experiences previously reserved for high-end establishments.

Custom Packaging Solutions

While traditional packaging creates waste after disposal, custom packaging solutions now incorporate edible metals that transform the entire unboxing experience into part of your culinary journey.

You’re witnessing brands leverage gold and silver leaf to create luxurious experiences that differentiate their food products in competitive markets.

These sustainable packaging innovations offer three key advantages:

- Enhanced visual appeal – Edible metals create premium aesthetics for high-end confectionery and gourmet foods

- Improved transparency – Nutritional information displays directly on edible packaging surfaces

- Waste reduction – Natural-source materials eliminate disposal concerns while meeting consumer sustainability preferences

You’ll find the global edible packaging market expanding rapidly as manufacturers recognize consumer demand for innovative, eco-friendly solutions that combine functionality with visual impact across culinary applications.

Cost-Effectiveness and Economic Advantages for Food Producers

When you incorporate edible metals into your food printing operations, you’re investing in a strategy that can considerably boost your bottom line.

The cost-effectiveness of edible metals like gold and silver leaf becomes evident when you consider their ability to command premium pricing. Food producers who utilize these materials can differentiate their products in a competitive market, creating unique selling propositions that justify higher costs.

You’ll find that initial sourcing expenses are often offset by increased revenue from high-end clientele seeking exclusive dining experiences. The enhanced visual appeal drives consumer interest and sales while streamlined production processes reduce waste.

Overcoming Technical Challenges in Edible Metal Formulations

As you shift from cost considerations to the practical implementation of edible metal printing, you’ll encounter several technical challenges that demand innovative solutions.

Successfully formulating edible inks requires addressing multiple critical factors that directly impact your printing outcomes.

Edible ink formulation presents complex technical hurdles that significantly influence the quality and consistency of your final printed results.

The key technical challenges you’ll need to overcome include:

- Viscosity optimization – You’ll need specialized binders and additives to achieve proper flow properties of edible inks, preventing nozzle clogging and guaranteeing smooth layer deposition.

- Particle uniformity – Maintaining consistent particle size distribution in your edible metal powders prevents printing inconsistencies and equipment malfunctions.

- Heat stability – Developing formulations that withstand printing temperatures without degrading guarantees the properties of edible metals remain intact throughout the entire process.

Frequently Asked Questions

Is 3d-Printed Meat Safe to Eat?

You can safely eat 3D-printed meat when it’s produced under FDA regulations using food-grade materials. Advanced monitoring technologies guarantee nutritional quality, while antimicrobial agents enhance freshness and reduce foodborne illness risks effectively.

What Are Three Problems With 3D Printing Food?

You’ll face ingredient limitations since foods must be paste-like and viscous. You’ll struggle with structural collapse when softer foods can’t support multiple layers. You’ll encounter nutritional alterations during processing.

Is PLA Food Safe FDA Approved?

Yes, you’ll find that PLA is FDA-approved for food contact applications. You can safely use it for food packaging and service items since it’s made from renewable corn starch or sugarcane sources.

What Things Are Illegal to 3D Print?

You can’t legally 3D print firearms, controlled substances, copyrighted designs without permission, explosive devices, counterfeit currency, or items intended for malicious purposes. These restrictions protect public safety and enforce intellectual property laws.

Leave a Reply