You’ll dramatically transform your cardiovascular device development by 3D printing prototypes in just 20 minutes instead of waiting 150 days with traditional methods. This technology enables patient-specific customization using CT or MRI scans, creating devices tailored to individual anatomies with 0.4mm accuracy. You’ll reduce costs greatly—full heart models cost $10 versus thousands using conventional manufacturing. Plus, you can rapidly iterate designs, enhance surgical planning, and accelerate FDA approval processes while exploring the revolutionary potential ahead.

Rapid Prototyping Accelerates Development Timelines

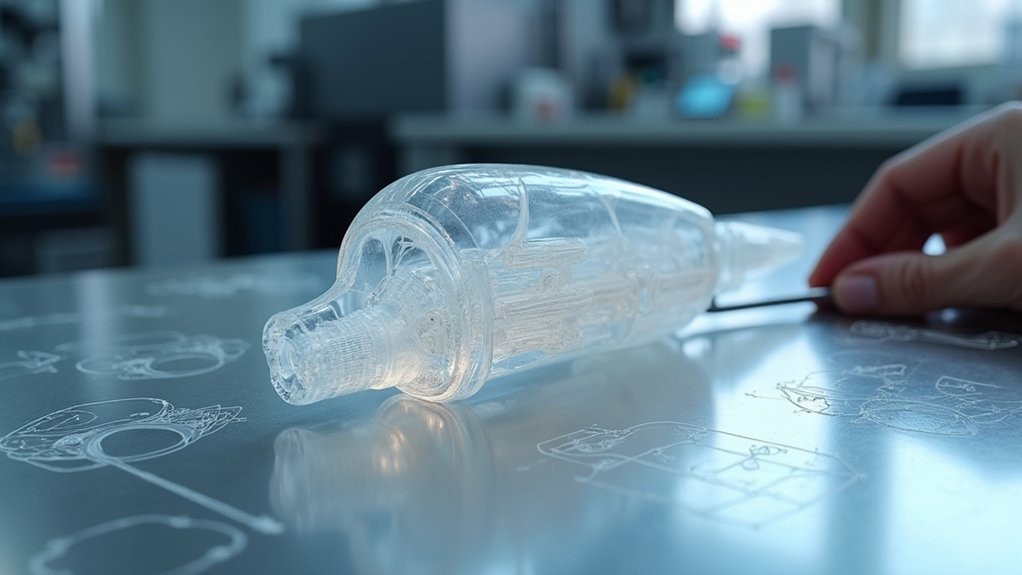

While traditional cardiovascular device manufacturing can stretch across several months, 3D printing transforms this timeline dramatically by producing personalized stents in as little as 20 minutes.

You’ll find that rapid prototyping enables immediate design iterations, allowing you to test and refine device features quickly. This printing technology proves critical in cardiovascular medicine’s fast-paced environment where time directly impacts patient outcomes.

When you’re developing personalized implants, 3D printing lets you create custom prototypes tailored to individual patient anatomies.

You can shift from concept to clinical application faster than ever before. The development of new cardiovascular devices benefits tremendously from this accelerated timeline, as you can identify ideal functionalities immediately.

Companies like Medtronic demonstrate how you can transform surgeon ideas into functional prototypes within a single day.

Patient-Specific Customization Enhances Treatment Outcomes

Beyond speed advantages, 3D printing’s most transformative capability lies in creating cardiovascular devices tailored to each patient’s unique anatomy.

You’ll benefit from patient-specific devices that utilize your MRI or CT scan images to replicate your heart’s natural geometry, improving accuracy in detecting irregularities. Custom 3D-printed cardiac catheters can measure electrical activity over specific regions of your heart, enhancing precision in rhythm disorder interventions.

Personalized cardiac devices replicate your heart’s exact geometry from medical scans, delivering unprecedented precision in detecting irregularities and treating rhythm disorders.

For cardiovascular applications, you’ll experience dramatically reduced wait times—personalized stents can be produced in 20 minutes instead of 150 days.

Studies demonstrate that 3D-printed vascular grafts support endothelial cell growth for at least six months. With mean deviation of only 0.4 mm between printed models and medical images, 3D printing delivers exceptional accuracy that directly improves your treatment outcomes.

Cost-Effective Testing and Design Iteration

You’ll slash development expenses dramatically when you replace costly traditional manufacturing with 3D printing—creating full heart models for just $10 compared to methods that previously required thousands of dollars and months of waiting.

You can validate your prototype designs in minutes rather than weeks, transforming what used to be a 150-day process into a 20-minute sprint for patient-specific devices.

You’ll iterate through multiple design revisions rapidly, testing and refining your cardiovascular devices without the financial burden that once limited innovation cycles.

Reduced Development Expenses

Three-dimensional printing dramatically cuts cardiovascular device development expenses by streamlining the prototyping process.

You’ll slash production timelines from 150 days to just 20 minutes for patient-specific stents, eliminating costly manufacturing delays.

3D printing enables reduced development expenses through affordable materials like biodegradable polymers and photosensitive resins, replacing expensive traditional raw materials.

You can create personalized designs for individual patient anatomies without the high tooling costs of conventional methods.

The financial impact is considerable—you’ll spend approximately $10 for a simplified heart model compared to considerably higher conventional manufacturing costs.

Cardiovascular devices benefit from rapid iteration capabilities, allowing you to test multiple design variations without expensive retooling.

This technology transforms development economics by reducing material waste, labor expenses, and time-to-market constraints while maintaining quality standards.

Rapid Prototype Validation

When cardiovascular engineers need to validate complex device designs, 3D printing transforms the testing landscape by delivering functional prototypes in minutes rather than months.

You’ll experience dramatically accelerated validation cycles, moving from traditional 150-day production timelines to just 20 minutes for initial prototypes. This speed enables real-time design modifications based on immediate testing feedback.

Patient-specific prototypes created through rapid prototyping enhance your validation accuracy by replicating individual anatomical structures with mean deviations of only 0.4 mm from medical images.

You can quickly iterate designs, testing multiple configurations within hours rather than waiting months between versions. This iterative approach improves device functionality while reducing validation costs to approximately $10 per full heart model, making thorough testing economically feasible for cardiovascular devices.

Enhanced Surgical Planning Through Anatomical Models

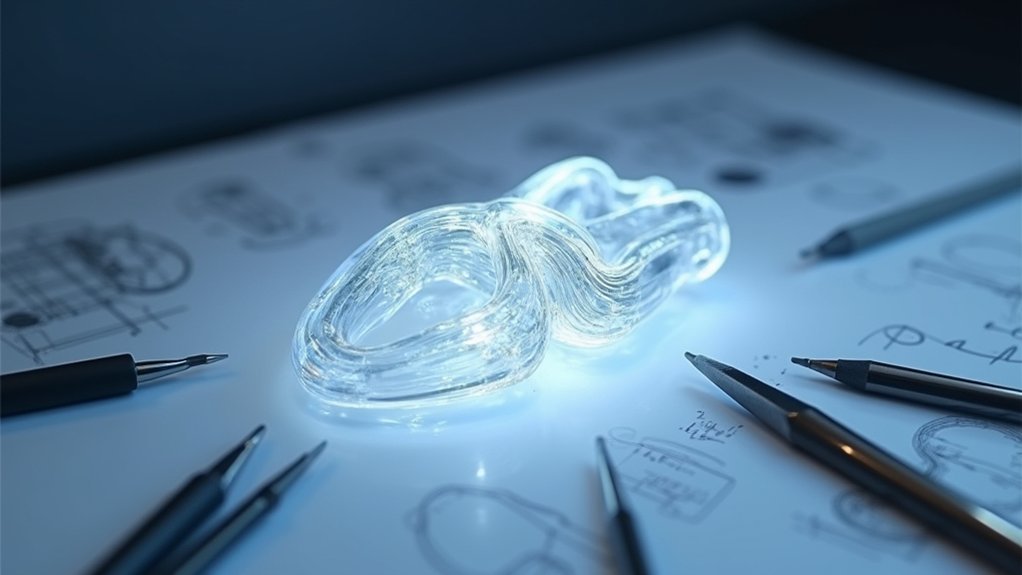

Precision becomes paramount when surgeons face complex cardiovascular procedures, and 3D printed anatomical models now provide the tangible clarity they need to navigate intricate patient-specific anatomy.

Through 3D printing, you can create detailed replicas of cardiovascular structures that achieve remarkable accuracy—within 0.4 mm of medical images, with high-resolution models reaching 0.15 mm precision.

These anatomical models transform your surgical planning by enabling individualized preoperative simulations where you’ll rehearse procedures and anticipate potential challenges before entering the operating room.

You’ll find that dynamic models facilitate hemodynamic testing, allowing better assessment of blood flow patterns. This enhanced preparation directly translates to reduced operating times and improved surgical outcomes, particularly when managing structural heart diseases and congenital defects.

Functional Prototypes Enable Hemodynamic Testing

While static anatomical models excel at visualizing patient-specific structures, functional prototypes take cardiovascular testing to the next level by incorporating dynamic blood flow simulation capabilities.

You’ll find that 3D printing enables creation of cardiovascular models that replicate your patient’s exact anatomy while allowing realistic hemodynamic testing through flexible materials that mimic tissue properties.

These functional prototypes provide tangible representations of complex cardiac structures, enhancing your surgical planning and execution strategies.

These precise cardiac models transform surgical planning by delivering hands-on visualization of patient-specific anatomical complexities before entering the operating room.

You’ll appreciate the significant time and cost savings compared to traditional rigid models, while maintaining exceptional accuracy with mean deviations of just 0.4 mm from medical images.

This precision makes hemodynamic testing with 3D-printed prototypes a reliable clinical tool for understanding blood circulation dynamics and cardiac function impacts.

Material Innovation Drives Advanced Device Properties

As cardiovascular device development advances, you’ll discover that cutting-edge materials are revolutionizing the properties and capabilities of 3D-printed prototypes.

Material innovation in cardiovascular devices now encompasses sophisticated polymers that enhance both biocompatibility and functionality.

- Biodegradable and nonbiodegradable polymers enable vascular grafts and stents that support endothelial cell growth while preventing platelet adhesion, dramatically improving device performance.

- Soft cell-laden materials like gelatin and hyaluronic acid create hydrogels that closely mimic biological tissue structure, advancing regenerative therapy applications.

- Cost-effective polymers including PLA and ABS allow precise anatomical replication for patient-specific devices, improving surgical outcomes.

You’ll find that ongoing research into mechanical properties demonstrates 3D printing produces cardiovascular devices with performance comparable to traditional manufacturing methods, positioning them for widespread clinical adoption.

Regulatory Pathway Advantages for 3D Printed Devices

You’ll find that 3D printed cardiovascular devices can navigate FDA approval processes more efficiently than traditional manufacturing methods, thanks to evolving regulatory guidelines that recognize their innovative potential.

Your clinical trials benefit from rapid prototyping capabilities that allow you to iterate designs in just 20 minutes, accelerating the testing and validation phases considerably.

You can also leverage the personalized nature of 3D printed devices to demonstrate improved patient outcomes, which strengthens your regulatory submissions and appeals to FDA assessments focused on efficacy.

FDA Approval Acceleration

Because 3D printing technology demonstrates such promising potential for cardiovascular devices, the FDA has established streamlined regulatory pathways that can dramatically accelerate your approval timeline.

These expedited processes recognize that 3D printing enables rapid prototyping and personalized solutions that traditional manufacturing can’t match.

The FDA’s approach to accelerating approval includes:

- 510(k) Premarket Notification Process – You can leverage existing guidance for additive manufacturing to submit applications through this faster pathway.

- Reduced Timeline Expectations – Your concept-to-clinical timeframe can shrink from over a year to just months through rapid prototyping capabilities.

- Clinical Evidence Support – Growing safety and efficacy data for 3D-printed cardiovascular devices builds regulatory confidence, facilitating quicker market pathways.

Your customized devices demonstrate improved clinical outcomes, supporting faster FDA approval decisions.

Clinical Trial Benefits

When you leverage 3D printing for cardiovascular device prototypes, your clinical trials gain unprecedented advantages that traditional manufacturing simply can’t deliver.

You’ll dramatically accelerate your research timeline, transforming prototypes that once required 150 days into devices ready in just 20 minutes. This speed enables rapid iterative testing, letting you optimize designs quickly before full-scale trials begin.

Your patient-specific prototypes created through 3D printing enhance trial relevance by accurately reflecting individual anatomical variations. This customization improves effectiveness and outcomes while facilitating smaller, more focused studies.

You’ll reduce overall costs considerably while conducting more targeted interventions. The technology’s regulatory acceptance by agencies like the FDA further streamlines your approval process, making clinical trials more efficient and successful than ever before.

Market Growth Signals Industry Transformation

The explosive growth trajectory of the 3D printed medical devices market tells a compelling story of industry transformation.

You’re witnessing unprecedented market expansion from $3.41 billion in 2022 to a projected $17.76 billion by 2032, representing a remarkable 17.94% CAGR. This isn’t just numbers—it’s evidence that personalized medical devices are reshaping healthcare’s future.

The market growth reflects three critical shifts:

- Healthcare providers increasingly demand customized solutions that improve patient outcomes

- Regulatory agencies like the FDA are adapting guidelines to support 3D printing adoption

- Technology innovations are closing the gap between research and clinical application

You’ll find that this transformation directly impacts cardiovascular device development.

As 3D printing technology advances, you’re gaining access to more sophisticated prototyping capabilities that enhance surgical precision.

Frequently Asked Questions

What Is the Main Benefit of Using 3D Printing in Cardiovascular Care?

You’ll benefit most from 3D printing’s ability to create personalized cardiovascular devices that replicate your unique anatomy, improving diagnostic accuracy and treatment outcomes while dramatically reducing production time from months to minutes.

Why Is 3D Printing Good for Prototyping?

You’ll rapidly iterate designs and test modifications quickly with 3D printing. It lets you create complex internal structures, achieve high accuracy, and greatly reduce production time compared to traditional prototyping methods.

Why 3D Printing Is Used for Custom Medical Devices?

You’ll get patient-specific devices that perfectly match individual anatomy using MRI or CT scan data. This customization dramatically reduces production time from 150 days to just 20 minutes while improving fit and treatment outcomes.

What Is the Main Advantage of Using 3D Printing in Surgical Simulation?

You’ll gain realistic haptic feedback and tangible anatomical representations that let you practice complex procedures beforehand. This hands-on experience improves your familiarity with patient-specific anatomy, enhancing surgical planning and confidence.

Leave a Reply