You’ll need to conduct five essential tests for your 3D printed medical prototypes: mechanical testing to assess tensile and compressive strength, biocompatibility testing following ISO 10993 standards to guarantee patient safety, dimensional accuracy verification maintaining tolerances of ±0.1-0.5mm, sterility assurance testing using validated sterilization methods, and performance testing under simulated clinical conditions. These evaluations determine regulatory compliance and identify design flaws early in development, guaranteeing your prototypes meet safety standards before clinical applications.

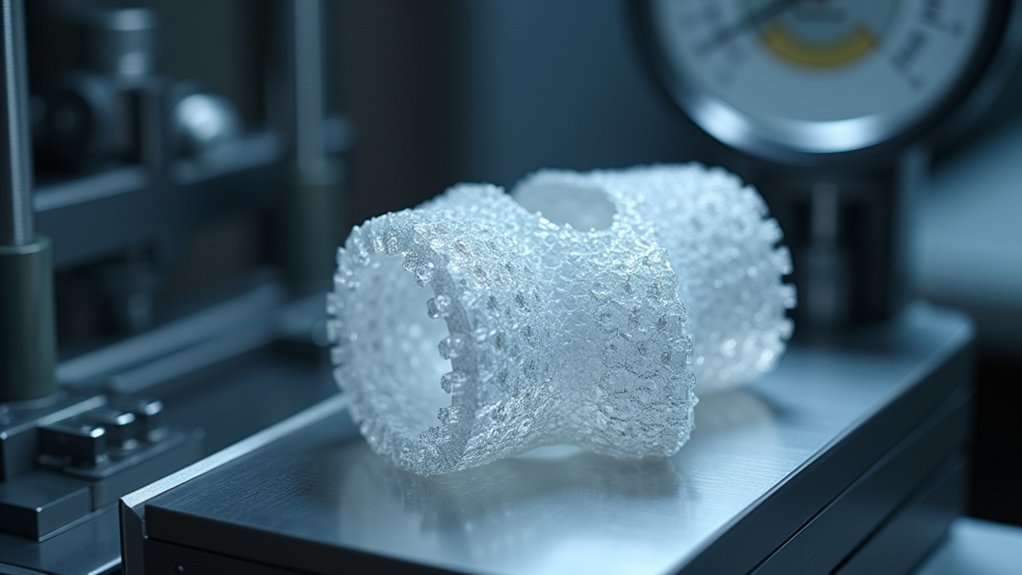

Mechanical Testing for Strength and Durability Assessment

When you’re developing 3D printed medical prototypes, mechanical testing serves as your first line of defense against potential device failures in clinical settings.

You’ll need to conduct three vital assessments to evaluate strength and durability effectively.

Tensile tests reveal your material’s maximum load capacity before breaking, measuring ultimate tensile strength and elongation—essential data for implants and surgical tools.

Compressive tests show how your 3D printed prototypes handle axial loads, important for weight-bearing orthopedic devices.

Flexural tests determine resistance to bending forces, particularly significant for devices experiencing deformation during use.

These performance assessments directly influence your material selection and design modifications, ensuring your prototypes meet rigorous safety standards required for medical applications.

Biocompatibility Testing for Patient Safety Validation

Beyond mechanical performance, your 3D printed medical devices must undergo rigorous biocompatibility testing to validate patient safety before clinical implementation. ISO 10993 regulatory standards mandate thorough assessments based on your device’s intended use and tissue contact duration.

| Test Type | Purpose |

|---|---|

| Cytotoxicity | Evaluates cellular toxicity and viability |

| Sensitization | Identifies potential allergic reactions |

| Irritation | Assesses tissue inflammation responses |

Manufacturers like Formlabs conduct these specific biocompatibility evaluations to confirm compliance with regulatory requirements. Your testing protocol varies depending on contact duration and tissue interaction type. Failure to meet these standards results in device rejection and costly development setbacks. You’ll need continuous monitoring throughout your device’s lifecycle to maintain compliance and assure patient safety from prototype through commercial deployment.

Dimensional Accuracy Verification and Tolerance Analysis

While biocompatibility guarantees your 3D printed medical prototype won’t harm patients, dimensional accuracy verification confirms it’ll perform its intended function precisely.

You’ll need to measure physical dimensions against your CAD models, typically maintaining tolerances between ±0.1 mm to ±0.5 mm depending on your medical applications.

Your tolerance analysis assesses how variations in the manufacturing process affect final dimensions, identifying potential production issues early.

You’ll require precise measurement tools like calipers and coordinate measuring machines (CMM) for accurate verification.

Technologies like SLA and SLS achieve dimensional accuracy upwards of 98%, making them ideal for intricate medical applications.

Regular tolerance analysis during prototyping greatly reduces costly design changes and guarantees regulatory compliance for your final medical device production.

Sterility Assurance Testing for Clinical Applications

Since your 3D printed medical prototype will likely contact patients or sterile environments, you’ll need rigorous sterility assurance testing to eliminate infection risks.

This validation guarantees your medical prototypes are free from viable microorganisms before clinical applications.

Your sterility assurance testing protocol should include:

- Bioburden testing – Quantify microorganisms present on your device before sterilization to determine appropriate sterilization methods.

- Sterilization validation – Verify ethylene oxide, gamma radiation, or steam sterilization effectively eliminates pathogens on your specific prototype materials.

- Regulatory compliance – Follow ISO 11737 and ISO 17665 guidelines for proper validation procedures and documentation requirements.

- Post-sterilization sterility testing – Conduct final sterility testing per ISO 11737-2 standards to confirm successful sterilization.

This thorough approach protects patients while meeting regulatory expectations for clinical use.

Performance Testing Under Simulated Use Conditions

After confirming your prototype’s sterility, you’ll need to validate its performance under simulated use conditions that mirror real-world clinical scenarios. Performance testing of 3D printed medical prototypes guarantees they meet safety standards and effectiveness requirements before patient use.

You’ll conduct stress, fatigue, and wear testing under conditions that replicate actual operational environments, including specific temperatures, humidity levels, and mechanical loads. Regulatory agencies require this data to approve your final medical device for market entry.

| Test Type | Purpose |

|---|---|

| Stress Testing | Evaluates maximum load capacity |

| Fatigue Testing | Assesses repeated use durability |

| Wear Testing | Measures material degradation |

Testing results help identify design flaws early, allowing you to make necessary modifications that enhance your prototype’s safety and clinical effectiveness.

Frequently Asked Questions

What Are the Challenges of Using 3D Printing in the Medical Field?

You’ll face regulatory approval delays, expensive biocompatible materials, skilled operator shortages, slower production speeds, and confusing FDA versus state board classifications that create legal uncertainties when implementing 3D printing technologies in medical applications.

What Is ASTM in 3D Printing?

ASTM develops voluntary technical standards you’ll use in 3D printing to guarantee quality and consistency. You’ll follow ASTM F42 committee guidelines for additive manufacturing materials, testing procedures, and safety requirements across various applications.

How to Check a 3D Model Before Printing?

You’ll run your model through mesh repair tools to fix holes and non-manifold edges, check dimensions in CAD software, verify material compatibility, and simulate printing to identify potential issues.

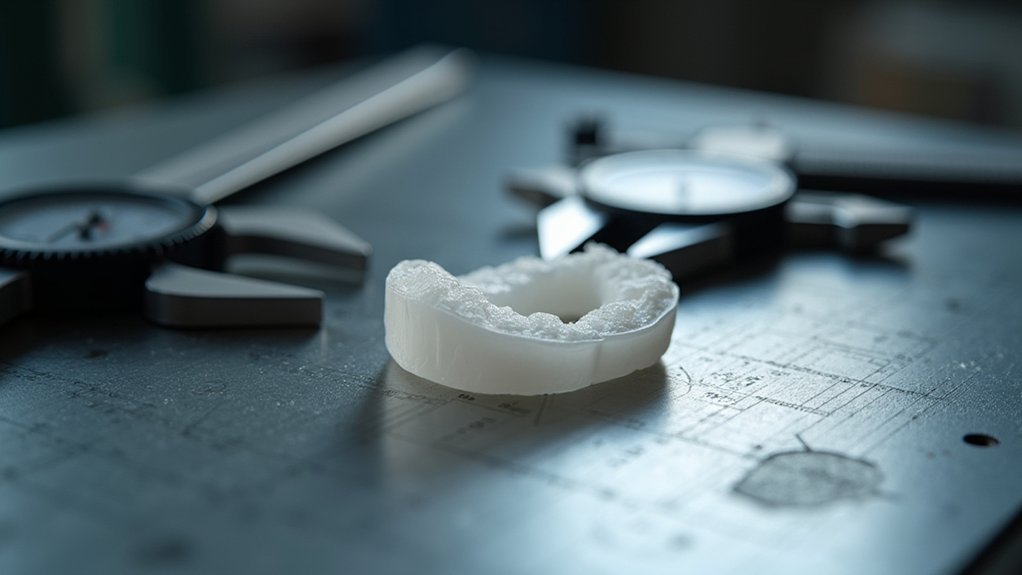

What Is an Example of a Real Life Application of 3D Printing in the Medical Field?

You’ll find custom dental aligners are a perfect example – they’re 3D printed using patient-specific models to guarantee better fit and comfort than traditional methods, revolutionizing orthodontic treatment effectiveness.

Leave a Reply