You’ll choose large scale 3D printing systems because they enable complex geometries impossible with traditional manufacturing while achieving exceptional precision with 25-micron resolution. You eliminate expensive molds and tooling, reduce material waste, and accelerate prototyping timelines considerably. These systems deliver full-scale prototypes in single prints, minimize assembly requirements, and adapt across aerospace, automotive, and architectural industries. You’ll streamline workflows, reduce production costs, and gain competitive advantages through mass customization capabilities that transform your manufacturing approach entirely.

Enhanced Production Capabilities for Complex Geometries

When you’re working with traditional manufacturing methods, you’ll often find yourself constrained by geometric limitations that force you to compromise on design innovation.

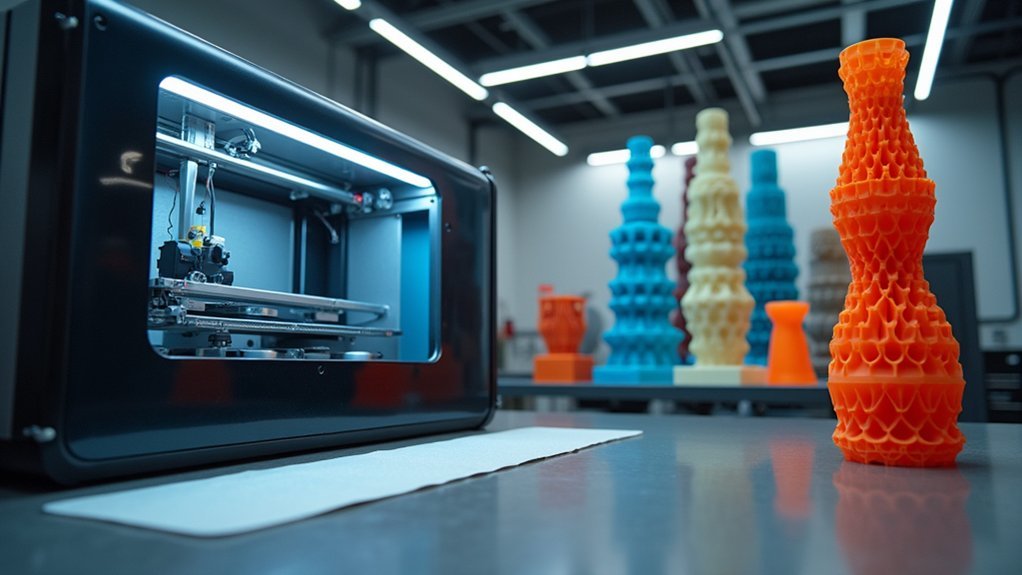

Large scale 3D printing revolutionizes your production capabilities by enabling the creation of complex geometries that would otherwise be impossible to manufacture. You can now develop intricate designs with internal structures, hollow sections, and interconnected features that enhance functionality while reducing material usage.

Advanced technologies like SLA and LFS deliver exceptional precision, allowing you to maintain tight tolerances even in large-format builds.

You’re able to optimize mechanical properties through strategic geometry placement and material distribution. This capability transforms how you approach product development, eliminating the need to simplify designs for manufacturability and instead embracing complexity as a competitive advantage in your engineering solutions.

Cost-Effective Manufacturing and Reduced Material Waste

You’ll find that large scale 3D printing eliminates your need for expensive molds and tooling, cutting traditional manufacturing setup costs considerably.

Your material usage becomes highly efficient since the process only uses what’s necessary for each print, dramatically reducing waste compared to conventional methods.

You can also minimize assembly requirements by producing complex parts as single pieces, reducing both labor costs and potential failure points.

Eliminates Traditional Tooling Costs

Traditional manufacturing methods burden you with substantial upfront investments in molds, dies, and specialized tooling that can cost thousands or even millions of dollars before you produce a single part.

Large scale 3D printers eliminates the need for expensive molds entirely, allowing you to go directly from digital design to finished product. This dramatic reduction in production costs makes manufacturing accessible for smaller production runs that wouldn’t justify traditional tooling expenses.

You’ll also benefit from reduced material waste since additive manufacturing only uses the exact amount needed for each component.

The rapid prototyping capabilities let you iterate designs quickly without redesigning expensive tools. Traditional manufacturing methods simply can’t match this cost efficiency, especially when you’re producing complex geometries or customized parts that would require specialized tooling.

Minimizes Production Material Waste

Beyond eliminating tooling expenses, large scale 3D printing revolutionizes material efficiency by using only what’s required for each part.

You’ll minimize production material waste since the technology deposits material precisely where needed, unlike traditional manufacturing that cuts away excess.

The ability to create intricate designs in single prints eliminates assembly requirements, further reducing waste.

You can streamline manufacturing process by producing unibody components that reduce potential weak points from joined parts, creating stronger products with less material.

The cost-effectiveness extends beyond initial savings—you’re avoiding multiple production steps and expensive molds while achieving superior resource efficiency.

This targeted approach transforms how you think about material usage in large-scale manufacturing.

Reduces Assembly Requirements

When large scale 3D printing produces entire components as single units, you’re eliminating complex assembly processes that traditionally require multiple manufacturing steps, skilled labor, and quality control checkpoints.

This capability allows you to reduce production time while maintaining structural integrity throughout your parts. You’ll find that assembly requirements become virtually nonexistent when components emerge complete from the printer, ready for immediate use.

The technology enables you to create intricate designs without worrying about how separate pieces will connect, giving you unprecedented design freedom.

Your manufacturing costs drop considerably since you’re streamlining the entire production workflow. You’ll no longer need specialized assembly equipment or extensive quality checks between multiple components, making your operations more efficient and cost-effective.

Accelerated Prototyping and Time-to-Market Advantages

As businesses face mounting pressure to bring products to market faster than ever, large scale 3D printing emerges as a game-changing solution that dramatically compresses development timelines.

You’ll achieve accelerated prototyping by considerably reducing production times compared to traditional manufacturing methods. This technology enables rapid iteration and design refinements that simply aren’t possible with conventional approaches.

You can create full-scale prototypes in single prints, eliminating assembly bottlenecks that typically slow development cycles. The cost-effective production model removes expensive tooling and mold requirements, allowing you to validate designs without heavy upfront investments.

Enhanced design freedom lets you quickly adapt to market changes and consumer demands, ensuring you’re first to market with innovative solutions that capture competitive advantages.

Superior Precision and Quality Control Standards

While speed to market remains essential, large scale 3D printing systems deliver unprecedented precision that transforms how you approach quality control in manufacturing.

You’ll achieve superior precision with XY resolution of 25 microns and laser spot sizes of 85 microns, dramatically outperforming traditional FFF methods.

This level of accuracy enables you to create intricate designs and complex geometries without mechanical constraints, opening new possibilities for innovative product development.

Versatile Applications Across Multiple Industries

You’ll find large scale 3D printing systems transforming industries through their remarkable versatility and adaptability.

From aerospace manufacturers creating lightweight composite components to automotive companies producing custom parts for specific vehicle models, these systems deliver tailored solutions that enhance performance and efficiency.

Whether you’re working in architecture to produce precise visualization models or need specialized tooling for industrial applications, large format printing technology adapts to meet your industry’s unique requirements.

Aerospace Manufacturing Applications

When you’re manufacturing aerospace components, large-scale 3D printing transforms how you approach production by enabling the creation of lightweight, single-piece structures that replace traditional multi-part assemblies. You can rapidly prototype complex geometries, accelerating design iterations and reducing time to market for new aircraft models.

| Component Type | Traditional Method | 3D Printing Advantage |

|---|---|---|

| Fuselage Sections | Multiple parts + assembly | Single unibody structure |

| Brackets & Ducts | Machined from solid blocks | Lightweight hollow designs |

| Engine Components | Multi-step manufacturing | Direct production of large parts |

| Structural Elements | Welded assemblies | Seamless integrated designs |

Advanced materials like high-strength composites meet rigorous aerospace standards while minimizing material waste. You’ll achieve significant weight reduction and improved fuel efficiency through optimized geometries impossible with conventional manufacturing.

Automotive Industry Solutions

The automotive industry leverages large-scale 3D printing to revolutionize vehicle development and production workflows.

You’ll accelerate your design process through rapid prototyping of complex components, enabling faster iterations and reduced time-to-market for new vehicles. Custom tooling and fixtures produced via large scale printing enhance your manufacturing efficiency by ensuring precise fit and functionality during assembly.

You can create lightweight parts using advanced materials that improve fuel efficiency without sacrificing strength or durability.

The automotive industry benefits from producing large, seamless components that reduce mechanical failure points compared to traditional methods requiring multiple smaller parts.

You’ll also achieve mass customization capabilities, allowing you to tailor designs and features to meet specific customer preferences efficiently.

Architecture and Construction

As large-scale 3D printing transforms the construction landscape, you’re witnessing a fundamental shift in how buildings and architectural elements come to life.

This manufacturing revolution enables you to produce detailed architectural models with exceptional precision, while creating large-scale structural components in single pieces that dramatically reduce assembly time.

You’ll benefit from:

- Accelerated project timelines – Noticeably faster completion compared to traditional construction methods

- Unlimited customization – Design unique structures tailored to specific requirements without manufacturing constraints

- Enhanced sustainability – Minimize material waste while utilizing eco-friendly materials

- Streamlined production – Print facades and structural elements as complete units, reducing potential failure points

Large scale 3D printing empowers you to embrace sustainable practices in architecture and construction while achieving unprecedented design flexibility and efficiency.

Streamlined Workflow Integration and Operational Efficiency

Since large-scale 3D printing systems transform traditional manufacturing paradigms, you’ll find they create unprecedented opportunities for streamlined workflows and operational efficiency. These large scale printers enable rapid prototyping that accelerates your concept-to-product timeline while reducing production complexity through automated processes.

| Workflow Stage | Traditional Method | Large Scale 3D Printing |

|---|---|---|

| Design to Prototype | 2-4 weeks | 1-3 days |

| Assembly Required | Multiple components | Unibody production |

| Manual Labor | High intervention | Automated processes |

| Error Rate | Variable quality | Consistent output |

| Production Speed | Sequential steps | Streamlined integration |

You’ll minimize manual labor through advanced software tools like Spatial’s 3D SDKs, which enhance visualization and manipulation capabilities. Regular maintenance guarantees consistent quality, while unibody part production eliminates assembly requirements, maximizing your operational efficiency.

Frequently Asked Questions

What Is Large-Scale 3D Printing?

You’ll use large-scale 3D printing to create objects several feet in size, exceeding traditional printer dimensions. You can produce precise, durable parts in one piece for aerospace, architecture, and automotive industries using specialized large-format printers.

Which Type of Printing Is Most Preferred for Large-Scale Production?

You’ll find FDM printing most preferred for large-scale production because it’s cost-effective and produces strong, lightweight parts using various thermoplastic materials, making it ideal for high-volume manufacturing needs.

Do I Need a Large 3D Printer?

You’ll need a large 3D printer if you’re creating objects exceeding 1000mm, require unibody parts for structural integrity, or want cost savings from reduced waste and eliminated tooling expenses.

Is Large-Scale 3D Printing Expensive?

You’ll face high upfront costs ranging from tens of thousands to hundreds of thousands of dollars, but you’ll save money long-term through reduced waste, faster production, and eliminated tooling expenses.

Leave a Reply