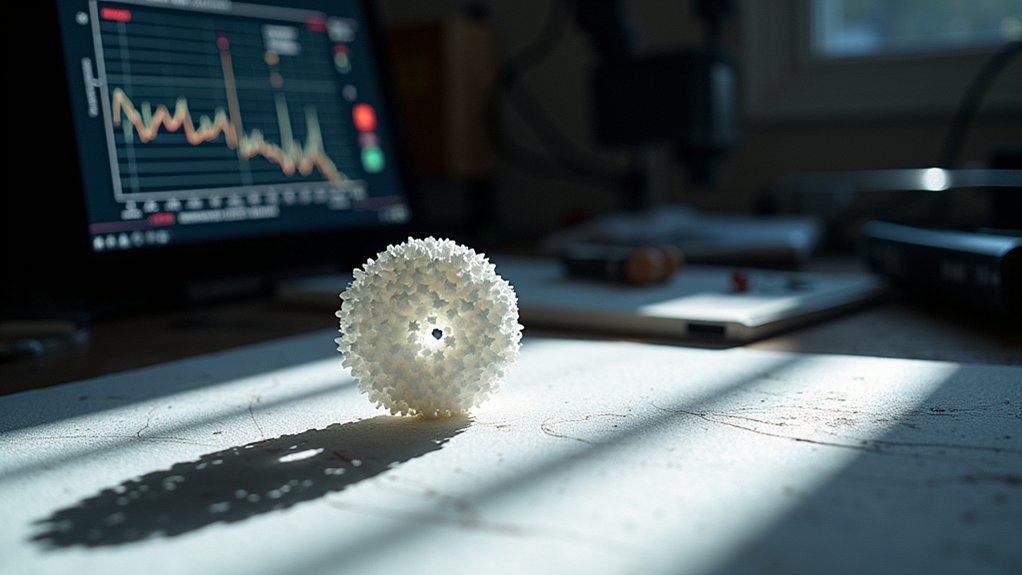

Your support settings fail because you’re choosing the wrong support type for your geometry and material combination. Tree supports work best for small, intricate overhangs while normal supports suit large, flat surfaces. You’re likely using incorrect threshold angles—30 degrees is standard, but complex models need 15-25 degrees. Poor gap settings between 0.1-0.5mm also cause removal issues. Material mismatches like PETG-PLA create weak adhesion points. Master these fundamentals to transform your printing success.

Understanding Normal Vs Tree Support Types

When you’re deciding between support types for your 3D prints, you’ll encounter two primary options: Normal Support and Tree Support.

Normal Support generates structures directly beneath overhangs, making it perfect for large, flat surfaces requiring consistent stability.

Normal Support creates direct structural foundations under overhangs, delivering reliable stability for large, flat printing surfaces.

Tree Support uses a branching structure that grows downward, efficiently supporting small or uneven overhangs while consuming less material.

Your choice impacts print quality considerably. Normal Support works best for larger overhangs due to its structural stability, while Tree Support excels with complex geometries through material efficiency.

Both support types automatically detect overhangs based on threshold angles, typically 30 degrees.

You can customize Normal Support with Grid and Snug styles, while Tree Support offers Slim Tree and Strong Tree options for optimized performance.

Choosing the Right Support Style for Your Model

Since your model’s geometry directly influences which support style will deliver the best results, you’ll need to evaluate several key factors before making your selection.

Consider these critical factors when determining which supports you need:

- Overhang size and complexity – Normal supports work best for large, flat overhangs, while Tree supports excel with intricate, uneven surfaces.

- Material efficiency goals – Tree supports use less filament and create cleaner removal paths.

- Support interface requirements – Snug Normal supports provide better surface quality for thin extensions.

- Adhesion to the model concerns – Adjust threshold angles from 30 degrees to minimize unnecessary material while maintaining proper bonding.

Choose Slim Tree for efficiency, Strong for durability, or Hybrid for balanced performance based on your model’s specific demands.

Setting Proper Threshold Angles for Overhang Detection

After selecting your support style, you’ll need to configure threshold angles to determine exactly where your slicer generates supports. The default 30-degree setting works for basic prints, but you’ll want to adjust it based on your model’s geometry. Lowering the threshold creates more supports, which is really good for complex overhangs and intricate details.

| Threshold Angle | Support Generation | Best Use Case |

|---|---|---|

| 15-25° | Heavy support inside model | Complex geometries |

| 30-35° | Moderate support coverage | General printing |

| 40-45° | Minimal supports | Simple overhangs |

| 50°+ | Very limited supports | Risk of failure |

| Custom zones | Selective placement | Mixed requirements |

Understanding how you would orientate your model affects these settings considerably, as improper angles cause print failures.

Optimizing First Layer Density and Adhesion

Once you’ve configured your threshold angles, you’ll need to focus on first layer density and adhesion settings to guarantee your supports remain stable throughout the printing process.

Your first layer density directly impacts how well supports stick to the build plate, affecting overall print success.

First layer density determines support adhesion strength, making it a critical factor in preventing print failures and ensuring successful builds.

Key optimization strategies include:

- Increase density to 20-30% as your baseline, then experiment with higher values for larger or heavier support structures

- Adjust first layer expansion to increase contact area between supports and build plate

- Verify proper bed leveling and nozzle height settings before each print

- Calibrate regularly and monitor first layer performance to maintain consistent results

Higher densities provide better stability but consume more material, so find the balance that works for your specific print requirements.

Configuring Support Interface Settings

When you’re configuring support interface settings, you’ll need to focus on two critical parameters that determine how well your supports interact with your model.

Interface layer adhesion controls how strongly the support material bonds to your print, affecting both support effectiveness and removal difficulty.

Z distance configuration sets the gap between your support interface and the model surface, directly impacting surface quality and the ease of support removal.

Interface Layer Adhesion

Interface layer adhesion determines how strongly your support structures bond to your model’s surface, and getting this balance right prevents both printing failures and model damage during support removal.

You’ll need to fine-tune these settings to avoid supports that either break during printing or damage your model when detached.

Key strategies for enhancing interface layer adhesion:

- Increase top Z distance in your slicer to reduce bond strength and make supports easier to remove

- Experiment with support styles like Snug or Grid for better surface quality and reduced material waste

- Adjust support density alongside interface settings to find the ideal adhesion level

- Test different combinations of interface settings to maintain print stability without creating overly strong bonds

Finding this balance guarantees your supports stay functional throughout printing while detaching cleanly afterward.

Z Distance Configuration

Since Z distance configuration controls the critical gap between your support structures and model surface, mastering this setting directly impacts both print quality and support removal ease.

You’ll find that setting the distance too high weakens support adhesion, causing failures mid-print when structures can’t maintain proper contact. However, you’ll struggle with damaged models if you set it too low, creating overly strong bonds that resist clean removal.

Start with 0.1 to 0.2 mm as your baseline, then adjust based on your specific material properties and model requirements. You shouldn’t rely on universal settings—different materials behave uniquely.

Instead, you’ll achieve better results by testing various distances systematically. Regular fine-tuning for each material and model type greatly improves your success rates while minimizing support-related printing problems.

Using Manual Support Painting Effectively

Although automatic support generation works well for basic prints, manual support painting gives you precise control over where supports are placed, allowing you to target only the areas that truly need them.

This selective approach prevents unnecessary supports that waste material and create unwanted marks on your model’s surface.

Manual support painting excels in complex geometries where automatic detection fails. You can paint supports directly onto intricate overhangs and internal holes that algorithms miss.

Take control of complex prints by painting supports exactly where automatic algorithms fall short.

Key benefits include:

- Precise targeting – Paint supports only where needed, reducing material waste

- Fine-tuned density – Adjust support strength in critical areas while maintaining removability

- Combined styles – Mix normal and tree supports for ideal performance

- Better finishes – Eliminate unnecessary supports that roughen visible surfaces

Adjusting Support Distance and Gap Settings

Once you’ve painted your supports exactly where you want them, fine-tuning the distance settings becomes your next optimization step. The support gap controls how much space exists between your supports and model surface. Most slicers default to 0.2mm, but you’ll want to experiment between 0.1mm and 0.5mm based on your specific setup.

A smaller gap improves surface quality but makes removal harder. A larger gap facilitates easier removal but may compromise surface smoothness.

Pay special attention to Z distance settings when using materials like PETG that bond aggressively to supports. Testing different combinations with your printer and filament is essential since results vary greatly across setups.

Start with your slicer’s default and adjust based on removal difficulty and surface finish requirements.

Material Compatibility Between Model and Supports

When you’re mixing PETG and PLA in your prints, you’ll encounter interface problems that can compromise your entire project.

The bond strength between these materials suffers during temperature switches, creating weak points where layers don’t properly adhere to each other.

You’ll need to carefully manage this compatibility issue since PETG’s higher printing temperature and different thermal properties don’t naturally mesh with PLA’s characteristics.

PETG PLA Interface Issues

Since PETG and PLA have fundamentally different thermal properties, you’ll encounter significant bonding challenges when using them together in a single print.

The temperature gap between these materials creates weak adhesion points that compromise your entire project.

The cooling process during filament switches amplifies these problems, causing separations and weak spots throughout your print.

Even when PLA supports remove easily, you’re left with poor surface finishes on your PETG model.

Key issues you’ll face include:

- Weak layer adhesion between PETG and PLA interfaces

- Print failures from temperature-related bonding problems

- Poor surface quality where materials meet

- Inconsistent results despite identical settings

You must experiment extensively with support configurations, as the interaction between these materials varies dramatically based on your specific print conditions and slicer settings.

Temperature Switch Bond Strength

Temperature differences between your model and support materials create the most critical bonding challenges you’ll encounter in multi-material printing.

When you’re changing between PLA and PETG, their different thermal properties cause varying cooling rates that weaken bond strength at interface layers. PLA’s lower adhesion temperature compared to PETG creates stress points that’ll cause your bond to break under load.

You’ll face insufficient fusion when your nozzle temperature drops too low during material changes, compromising support structure integrity.

Test and optimize your cooling settings for each material combination—inadequate cooling leads to weak layer adhesion and support failure.

Understanding specific thermal properties of your material pairing helps you select proper support settings and prevent adhesion issues before they ruin your prints.

Support Removal Techniques and Best Practices

Remove support structures carefully to preserve your model’s surface quality and structural integrity. Your removal technique directly impacts the final result, so you’ll want to optimize both your settings and approach.

Adjust your top Z distance to create easier separation between supports and your model. This prevents surface damage during removal while maintaining adequate support strength during printing.

Here are essential support removal best practices:

- Use scraper tools to remove stubborn support remnants without damaging your printed object

- Increase purge settings to improve support material adhesion and stability during printing

- Avoid placing supports inside channels or intricate areas unless absolutely necessary

- Consider seamless support options designed for easier removal and better print quality

These techniques will minimize post-processing time while protecting your model’s integrity.

Troubleshooting Common Support Generation Problems

When support structures fail to generate properly or create printing issues, identifying the root cause becomes your first priority for achieving successful prints.

Start by checking your threshold angle settings—if it’s too high, you’ll miss critical overhangs; too low creates unnecessary supports. The standard 30-degree setting works for most materials, but you’ll need adjustments based on your filament’s characteristics.

Finding the sweet spot for threshold angles is crucial—too high misses overhangs, too low wastes material with unnecessary supports.

Switch between Normal and Tree support types to match your print’s geometry. Tree supports excel with complex overhangs, while Normal supports provide better stability for large areas.

Use manual support painting to target specific problem zones your slicer might miss. Boost first layer density and expansion settings to prevent support detachment.

Finally, regularly review your settings against your filament’s unique properties for ideal performance.

Advanced Support Settings for Complex Geometries

When you’re tackling complex geometries, optimizing your interface layer settings becomes essential for achieving clean surface finishes where supports contact your model.

You’ll want to fine-tune parameters like interface density, thickness, and roof/floor patterns to balance easy removal with adequate support strength.

If you’re working with a multi-material printer, you can leverage soluble support materials or alternating filament strategies to handle intricate overhangs that would otherwise be impossible to support effectively.

Interface Layer Optimization

Although support structures are essential for printing complex geometries, they often create surface imperfections and require significant post-processing effort when removed.

You’ll dramatically improve your support removal experience by fine-tuning the interface layer between your supports and model.

The interface layer acts as a buffer zone that prevents supports from bonding too strongly to your print.

Here’s what you need to optimize:

- Adjust top Z distance – Increase spacing between support tops and model to reduce adhesion strength

- Configure interface density – Lower density creates weaker bonds for easier removal

- Set appropriate interface thickness – Multiple thin layers work better than single thick ones

- Enable support roof – Dedicated interface material provides cleaner separation

These adjustments guarantee your supports detach cleanly without damaging delicate surface details.

Multi-Material Support Strategies

Multi-material support strategies revolutionize how you approach complex geometries by leveraging different materials’ unique properties for ideal print outcomes.

You’ll find mixing PLA supports with PETG primaries creates excellent adhesion while ensuring smoother removal, preventing damage to your main print.

Configure advanced support settings by adjusting density, angle, and placement to accommodate intricate designs without compromising aesthetics or functionality.

Tree supports combined with multi-material setups boost material efficiency and structural integrity, especially for models with varying overhangs.

Fine-tune your slicer’s threshold angle and support parameters to minimize material usage while maximizing success rates.

You’ll discover that strategic material selection for supports transforms challenging prints into manageable projects, delivering superior surface finishes and reducing post-processing time considerably.

Frequently Asked Questions

How Do Different Slicer Software Compare for Support Generation Quality?

You’ll find PrusaSlicer excels at automatic support placement, while Cura offers extensive customization options. Simplify3D provides precise manual control, and newer slicers like OrcaSlicer combine smart algorithms with user-friendly interfaces effectively.

What’s the Typical Cost Difference Between Using Support Material Versus Printing?

You’ll spend 15-30% more on filament when using supports, plus extra time removing them. However, you’re saving potentially wasted prints from failures, making supports cost-effective for complex geometries.

Can I Reuse Failed Support Material for Future Prints?

You can’t reuse failed support material effectively. The plastic degrades during printing, becomes brittle, and won’t bond properly in new prints. It’s better to recycle it or use fresh filament for reliable results.

How Does Room Temperature Affect Support Structure Stability During Printing?

Room temperature directly impacts your support material’s adhesion and cooling rate. You’ll notice supports becoming brittle or warping in cold rooms, while excessive heat causes drooping and poor layer bonding, compromising structural integrity.

Which 3D Printer Models Handle Support Removal Most Effectively?

You’ll find resin printers like Elegoo Mars and Anycubic Photon handle support removal best since they’re water-soluble. For FDM printers, Prusa i3 MK3S+ and Ultimaker S3 offer excellent dual-extrusion capabilities.

Leave a Reply